Hydraulic Oil Spill Kits and Spill Trays

Flowtech

From nasty falls to environmental damage, accidental spills at the workplace can have devastating consequences. Luckily, spill kits come with a range of control equipment that can minimise the damage caused by liquid, oil or chemical spills. And while the worst may never happen, it pays to be prepared for both clean up and containment in case a spill does occur.

There are many different types of spill kits. Some spill control tools, such as absorbents and waste disposal bags, focus on containing leaks. Meanwhile, others are designed to minimise the impact of spills on the surrounding environment through chemically inert materials such as clay or rubber.

In simple cases of hydraulic oil spills, the first step is putting on protective equipment such as gloves and shoe covers. The second step usually involves placing absorbent socks around the spill area to stop the liquid from spreading while it’s being soaked up with absorbent pads. All spill kits come with handy waste disposal bags where the residual materials from the clean-up can be placed before being safely discarded.

Types of Hydraulic Spill Kit

There are three main types of spill kits:

- Standard spill kits for cleaning up non-hazardous liquids

- Oil and fuel spill kits for cleaning up oil-based liquids and hydraulic grease

- Chemical spill kits for cleaning up hazardous liquids

Standard Spill Kits

General purpose spill kits are designed for dealing with common workplace spills that involve water-based liquids, oils and fuels. They usually contain protective wear, grey-coloured absorbent pads and containment products such as socks and waste disposal bags.

Oil and Fuel Spill Kits

As their name suggests, oil and fuel spill kits are specifically designed to contain oil and fuel leaks. They come with water-repelling white absorbents that float, making them very effective at cleaning up hydrocarbons.

Chemical Spill Kits

Chemical spill kits — also called hazmat spill kits — are engineered for cleaning up spills that contain corrosive solvents and acids. These types of kits come with yellow-coloured absorbents for soaking up hazardous chemicals.

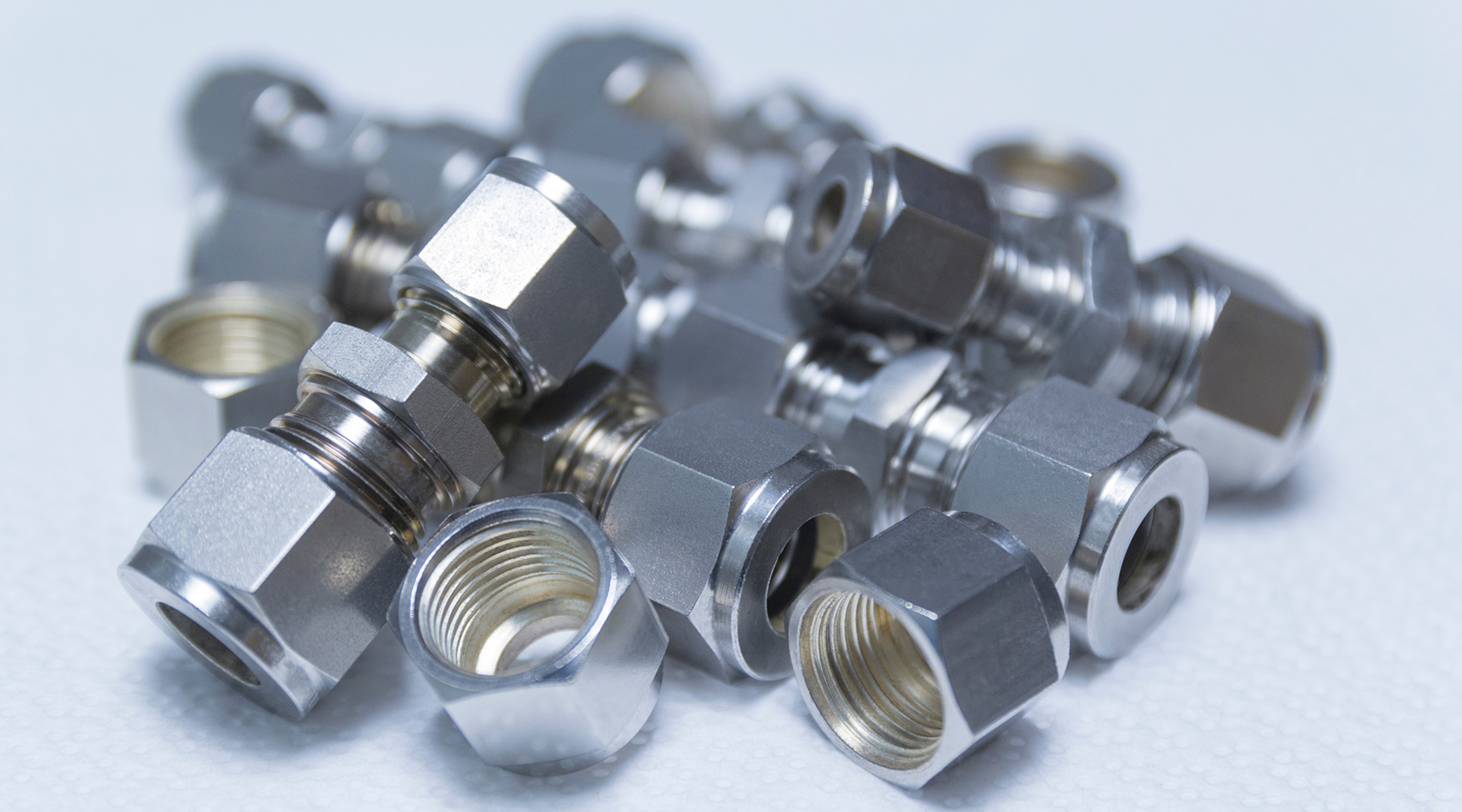

Spill Trays

Spill trays are one of the main components of most industrial spill kits. They are designed to stop spills and leaks from seeping into the ground in operational areas where fuel, oil or chemicals are present. Spill trays come in different sizes and litre capacities (some can hold up to hundreds of litres). On the most basic side, spill trays come in the form of trays with upturned sides that need to be emptied on a regular basis so as to not overflow.

Huge spill pallets, on the other hand, are used to temporarily store drums and barrels that may be leaking. They usually come with in-built oil separators, also called interceptors, that draw the fluid away to protect the drums or other containers. Spill pallets often feature four-way forklift access and are chemical-resistant.

FAQ's

How long does it take to clear up a spill?

Depending on the size of the spill, the entire clean-up job can take between minutes and hours. Dealing with most workplace spills, however, shouldn’t take more than a few minutes, provided that you have the right spill kit and equipment.

Whether in the form of a shoulder bag or a wheelie bin, spill kits come clearly labelled for quick response. Splash kits usually include personal protective equipment such as gloves, booties/shoe covers, goggles and a protective coat or apron. These should always be put on prior to dealing with a spill.

How does a spill kit work?

While there are different types of spill kits, they have all been designed to contain leaks and spills. Standard oil spill kits come with absorbent socks and pads that can be placed on and around the site of the spill to soak up fluid. Oil and fuel spill kits are designed to clean up engine oil, hydraulic oil and lubricating oil. They can also be used to deal with other hydrocarbons such as solvents and fuel. Meanwhile, chemical spill kits are used for cleaning up hazardous fluids.

In the case of hydraulic oil spills, what type of spill kit you use should depend on whether the spill area has been contaminated with water. If the oil spill isn’t contaminated with water, standard spill kits with grey pads and socks can be used to absorb any non-hazardous material. This makes them perfect for cleaning up not just oils, but also liquids such as coolants and paint.

Oil and fuel spill kits are ideal for cleaning up areas that may have been contaminated with water. This is because they both absorb oil and repel water. More specifically, the absorbent pads and socks that come in oil and fuel spill kits contain synthetic sorbents that attract oil molecules (they are oleophilic) and repel water (they are hydrophobic).

Normally white in colour, the absorbent materials soak up oils without absorbing water, which prevents them from quickly becoming soggy and waterlogged. As such, they are perfect for soaking up oil spills in water tanks, pools, ponds and streams. Most absorbent socks and pads change colour as they become saturated with fluid, making it easy to tell when they are ready to be placed in disposal bags.

What does a spill kit contain?

Spill kits contain all the tools and supplies required to deal with spills in an effective and efficient manner. While the exact content of a spill kit depends on its purpose — containing general spills, oil and fuel spills or hazardous material spills — all spill kits usually come with the following basic equipment:

- Personal protection equipment such as safety goggles, booties/shoe covers, gloves and coat or apron

- Absorbent pads to soak up the spill

- Absorbent socks to minimise the spreading of fluid

- Disposal bags to safely discard all residual materials

- Carry bag or wheelie container to store both equipment and waste

What size spill kit do I need?

While spill kits come in a variety of sizes, they are generally able to absorb between 50 and 240 litres of fluid. As a rule of thumb, the size of the spill kit should depend on the size of the potential spill. As such, you should ask yourself how much oil or other liquid you are storing at any given time. While a shoulder-bag sized spill kit is perfectly fine for small work areas, more spacious workplaces may require a larger spill kit. Larger work areas generally benefit from spill kits that come in drums with wheels for easier and faster transportation.

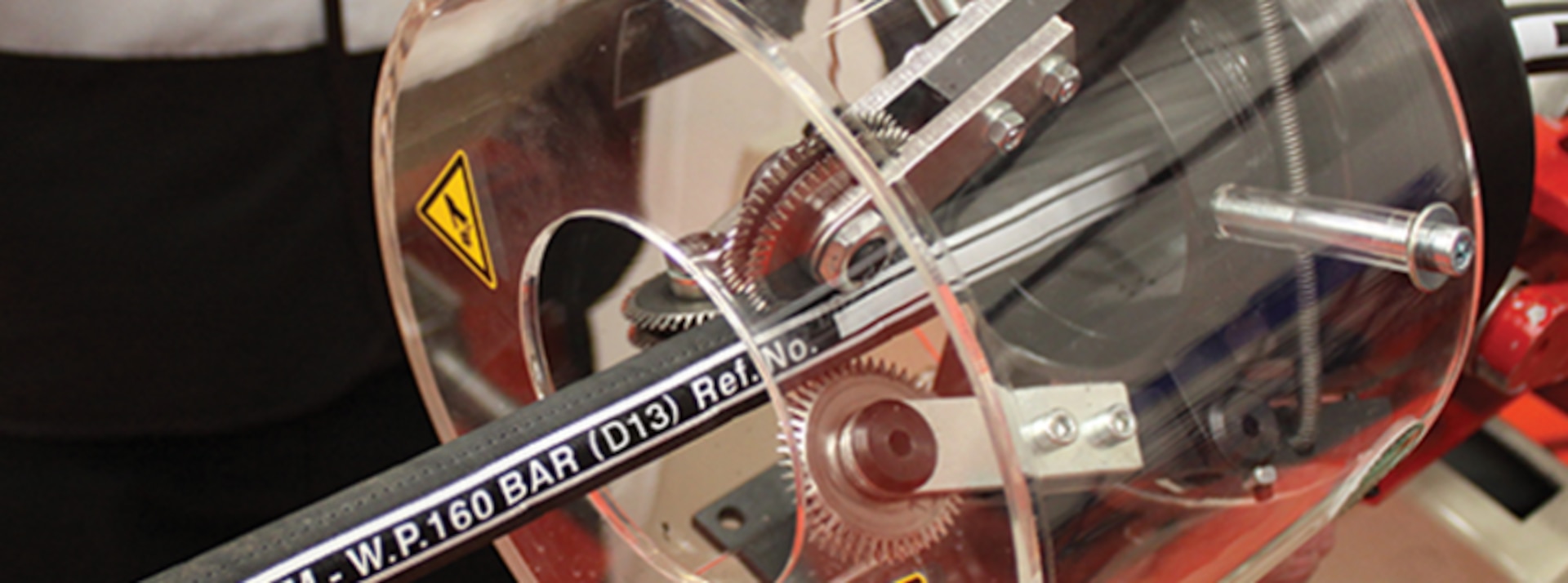

What is hydraulic grease?

Hydraulic grease is not the same as other mechanical lubricants. More than just a lube, it’s also a means of transferring power through a hydraulic system.

Just like other lubricants, to be effective, hydraulic grease needs to possess a number of properties. These include:

- Air release and foam resistance

- Oxidation, thermal and hydrolytic stability

- Anti-wear quality

- Filterability and the ability to separate water and oil

- Rust and corrosion resistance

- Viscosity (film thickness)

Since hydraulic grease is also a means of power transfer, it has to contain high bulk modulus to stop it from reducing in volume if placed under pressure and high viscosity index to ensure that it’s not affected by changes in temperature.

What is hydraulic grease made of?

Hydraulic grease is made up of three ingredients including oil, a thickener and other additives. Whether mineral or synthetic, oil is what gives hydraulic grease its lubricating properties. Oil makes up anywhere from 70% to 90% of hydraulic grease. In addition, hydraulic grease contains between 3% to 30% of thickener.