Hydraulic Gauges, Sight Glasses and Flow Meters

Flowtech

Hydraulic pressure gauges measure the intensity of fluid flow to minimise the risk of leaks. This is important because hydraulic systems operate within the parameters of a set pressure range. Any sudden pressure changes could jeopardise an entire hydraulic system. As such, hydraulic gauges are essential devices for setting up and maintenance of fluid power systems.

Even though the maximum hydraulic pressure of a system should not usually exceed 350 bar, hydraulic pressure gauges can detect pressures of up to 700 bar. While hydraulic gauges can be installed at many different points within a system, they are often placed close to a pump’s pressure port. They are also typically installed close to pressure-reducing valves to ensure that the set pressure settings are not exceeded. Hydraulic pressure gauges can be either analogue or digital.

Types of Hydraulic Pressure Gauge

Bourdon hydraulic pressure gauges

The most commonly used type of hydraulic pressure gauge, Bourdon pressure gauges feature a curved tube. An increase in pressure causes the tube to become less curved. This tiny movement, in turn, is transmitted to a needle deflection. Bourdon pressure gauges are usually made of stainless steel, brass or nickel alloy and can be used to measure pressure between - 1 and 1000 bar.

Membrane hydraulic pressure gauges

Membrane pressure gauges are usually used with corrosive liquids. Also referred to as diaphragm pressure gauges, membrane pressure gauges come with a diaphragm that bends when the pressure increases (they work on the Bourdon principle). Membrane hydraulic pressure gauges are usually used in low pressure systems and can measure pressure between - 1 and 40 bar.

Differential hydraulic pressure gauges

Differential pressure gauges indicate differential pressure by measuring the difference between two points of pressure within a hydraulic system. An increase of pressure between the two points can indicate contaminant buildup in filters, pumps or pipes. Differential pressure gauges can also be used to monitor flow, liquid levels and detect leaks. Differential gauges come in two types: piston differential pressure gauge and diaphragm differential pressure gauge.

Piezometer hydraulic pressure gauges

One of the simplest hydraulic pressure gauges on the market, piezometer hydraulic gauges come in the form of a simple tube made from glass. One end of the tube is connected to a pipe and the other remains open to the atmosphere. The tube is installed vertically enabling the fluid to rise in the tube. The medium pressure of the liquid is measured by looking at its level in the tube.

Hydraulic sight glasses

Usually made from borosilicate glass or soda-lime glass and metal frames, sight glasses are used to monitor the level of fluid in boilers, reactors, tanks and other vessels. Sight glasses are often used in the cosmetics, food-processing, pharmaceutical, distilling and chemical industries. There are three main types of hydraulic sight glasses:

- Circular sight glasses used to look into a vessel.

- Tubular sight glasses that are connected to the top and bottom of a tank.

- Sight flow glasses for observing flow in a pipeline

Hydraulic flow meters

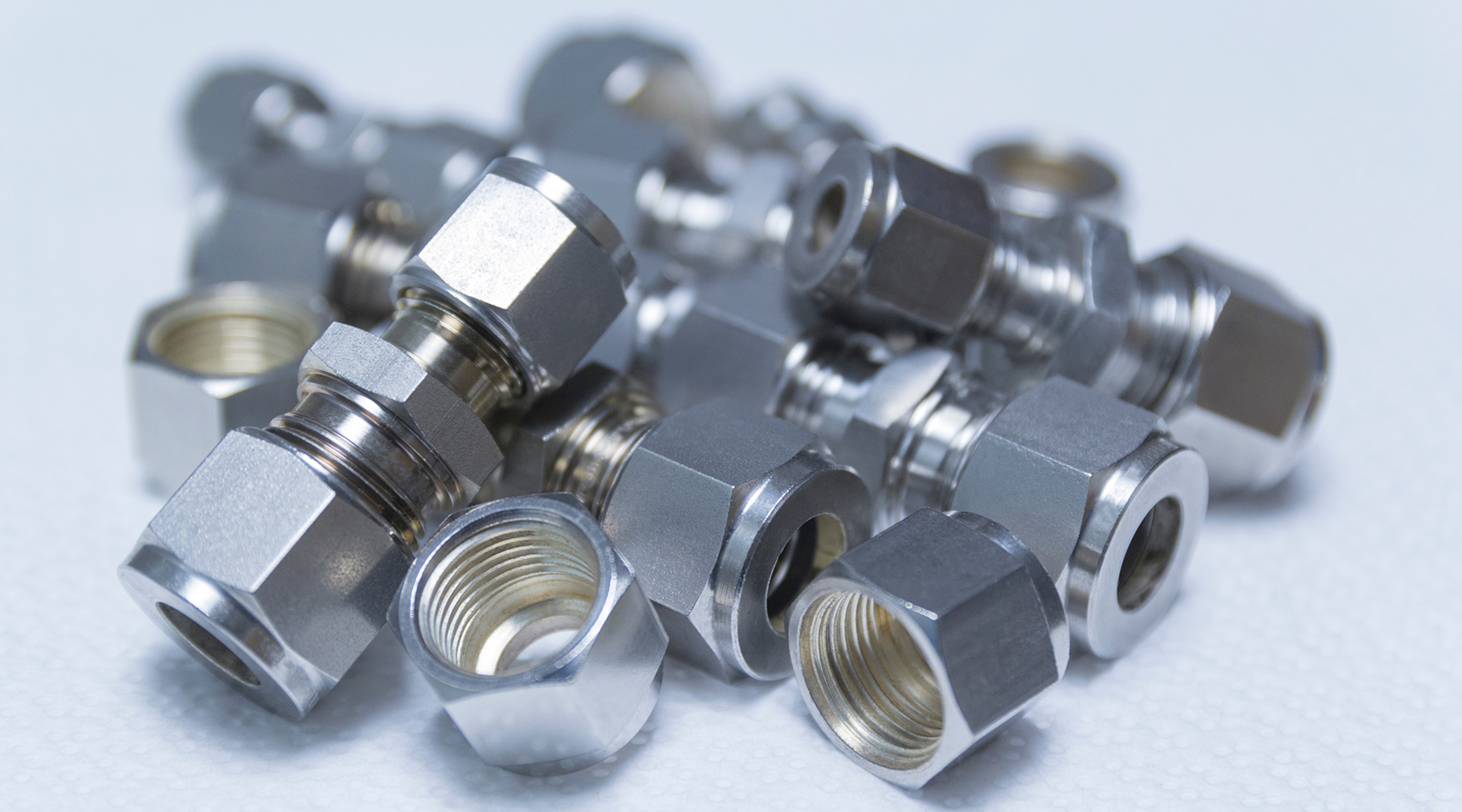

Unlike hydraulic gauges that are permanently installed in hydraulic systems, hydraulic flow meters are usually not a permanent part of a system. Also sometimes called liquid meters and flow indicators, water flow meters are used to measure mass or volumetric rate of flow. Hydraulic flow meters made from aluminium are used in systems that utilise water-based, petroleum-based or non-corrosive fluids with a pressure of no more than 240 bar. Brass water flow meters are used in water-based systems without corrosion inhibitors and pressure below 400 bar. Meanwhile, hydraulic flow meters made from stainless steel can be used with corrosive fluids in systems with pressure up to 400 bar.

There are certain things that need to be taken into account when selecting a hydraulic flow meter such as fluid type, operating conditions, level of accuracy and budget. With this in mind, here are the four most popular types of water flow meters:

- Vortex water flow meters feature a sensor that measures vortices or swirls formed by the flowing fluid. The sensor’s frequency output is proportional to the flow rate. Many multivariable vortex water flow meters can take different measurements including flow rate, volumetric flow rate, pressure, density, mass flow and temperature. This type of water flow meter is well suited to large pipes.

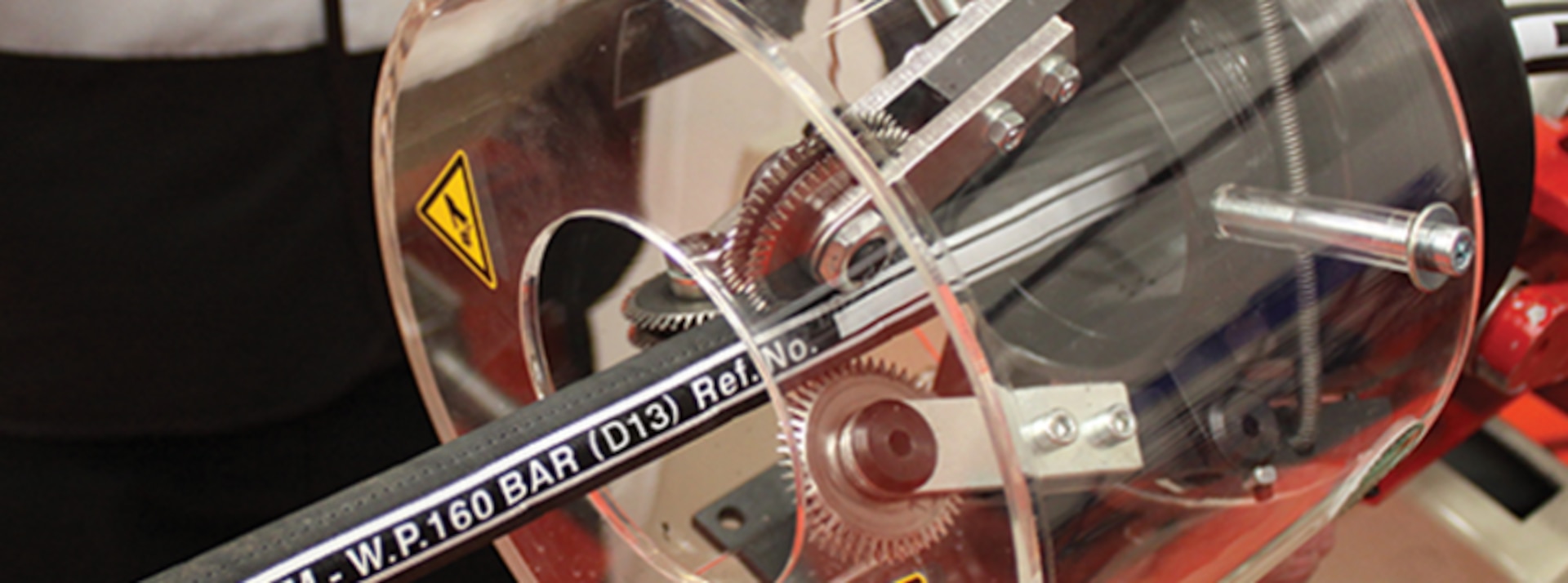

- Mechanical hydraulic flow meters measure volumetric flow by determining how fast a piston or a turbine within a system is rotating. The flow rate is proportional to the speed of the rotations. This type of water flow meter is affordable but does not operate well in low flows and can clog up if the water is not clean.

- Ultrasonic water flow meters measure volumetric flow rate by discerning the time it takes an ultrasonic signal to travel upstream and downstream and comparing the difference between the two times. Ultrasonic water flow meters can take measurements from outside piping systems by transmitting pulses through pipe walls.

- Magnetic hydraulic flow meters utilise a magnetic field to measure volumetric flow rate in a pipe. This type of water flow meter cannot be used to take measurements of pure water since it does not contain ions.

Hydraulic variable area flow meters

Variable area flow meters utilise the variable area principle to take measurements of the volumetric flow of liquids. Essentially, when a flow of liquid raises a float up, the volume of the fluid that passes through the meter increases. Hydraulic variable area flow meters are used in a variety of industries including oil and gas, mining and manufacturing.

Condition monitoring and contamination monitoring

Condition monitoring refers to the monitoring of various variables in relation to machinery such as temperature and vibrations to detect any changes that could indicate a potential problem. Condition monitoring is an important part of the maintenance of machinery, such as pumps, compressors and motors, and the prevention of potential system failures. Traditionally, condition monitoring revolved around measuring vibrations. Today’s modern devices, however, usually use sensors to measure various variables. Just as important, using devices for contamination monitoring can prevent costly problems and system failures.

When it comes to monitoring a system, the first step involves installing the appropriate monitoring devices. Besides flow speed and volume, some of the other measurements that you may wish to measure within a hydraulic system include temperature and vibration level. When monitoring the condition of a system, it is important to know the equipment’s baseline data measurements so its current performance variables can be compared to the variables during its optimum performance.