A Guide to Hydraulic Fittings

Flowtech

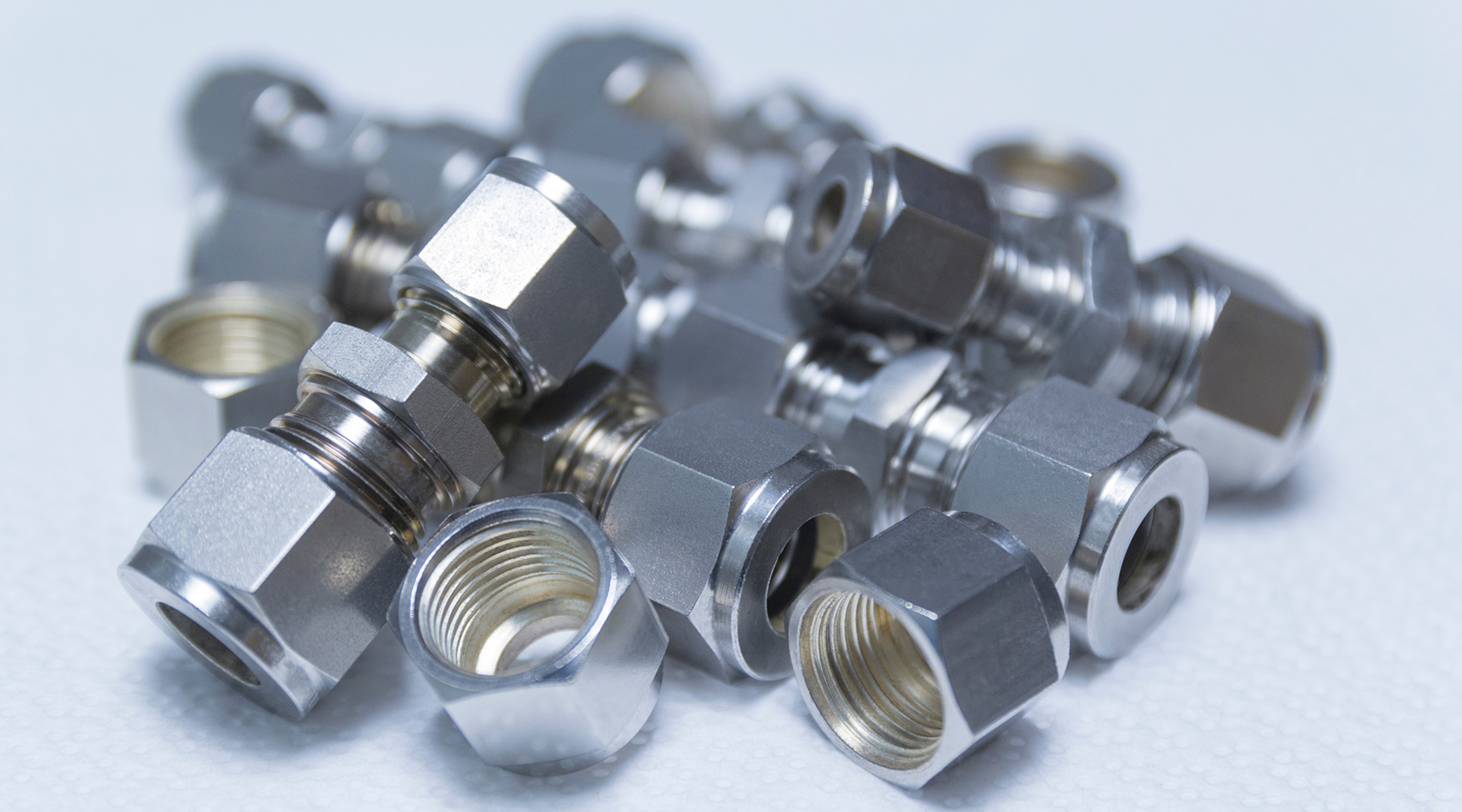

Hydraulic Fittings

Hydraulic fittings are designed to connect different parts of hydraulic systems including pipes, hoses and tubes to valves, pipes and other components. Made from materials such as stainless steel, plastic and brass, hydraulic fittings usually feature male or female threaded connections. Some of the most commonly used hydraulic fittings include adapters, hydraulic couplings, plugs, reducers, elbows and unions.

How are hydraulic fittings attached?

Hydraulic fittings can be attached in a variety of ways. These include.

- Threaded fittings come with threads on both ends that connect with other compatible threads. Not all threaded hydraulic fittings create a tight seal and may require additional seals or coating.

- Compression fittings use pressure as a seal. They usually utilize a compression nut and are watertight.

- Crimped fittings connect the hose to the fitting by crimping. The crimping process may require special tools.

Hydraulic Hose Fittings

Hydraulic hose fittings are either permanent or reusable. Also sometimes referred to as crimped hydraulic hose fittings, permanent hydraulic hose fittings are reliable, simple and quick to attach. Permanent hydraulic hose fittings are squeezed onto the hose and later discarded with the hose. They are often utilised in the fluid power industry. Reusable hydraulic hose fittings are usually fitted over the hose with the help of a wrench and a vice. Since reusable hydraulic hose fittings are more costly and difficult to install, they are rarely used today.

Shop hydraulic fittings

Types of Hydraulic Fittings Threads

There are many different fitting types. Here are some of the most common.

- NPT: Commonly used in North America, national pipe taper (NPT) fittings feature a tapered internal diameter and a tapered external diameter. They are self-sealing.

- BSPT: British standard pipe taper (BSPT) fittings are very similar to NPT except they feature a 55-degree angle (instead of a 60-degree angle) from the root to the crest.

- SAE: Society of automotive engineers (SAE) fittings are reusable and feature superior sealing due to their 90-durometer O-Ring.

- Metric taper: Commonly used in Europe, matric taper features precise internal and external diameters.

FAQ's

What does JIC mean in hydraulic fittings?

Joint industry council fittings, or JIC fittings, feature parallel threads and a 37-degree seat. Usually made from brass, nickel alloys, stainless steel and carbon, JIC hydraulic fittings have three main components: fitting, sleeve and flare nut. JIC hydraulic fittings are popular because they come in a huge range of shapes, sizes and materials. Plus, they are simple to install and can be removed and reinstalled without deformation. On the downside, JIC hydraulic fittings are not recommended for high-vibration applications due to their low pressure rating.

How do you determine what hydraulic pipe fitting to use?

An incorrect hydraulic fitting and hose combination can lead to fluid leaks. As such, you need to ensure that you have the correct hydraulic pipe fitting for the job. This involves finding a hydraulic fitting with the right diameter, length, thread and angle. It is best to use a measuring tape to work out the length of the hydraulic fitting and a caliper to determine its external and internal diameters.

Are JIC and NPT the same?

Available in different shapes and sizes, joint industry council (JIC) fittings are used in high pressure systems. Meanwhile, national pipe taper (NPT) fittings are used in low pressure systems. While they can both be used in hydraulic systems, JIC and NPT fittings are not interchangeable.

What is the difference between SAE and NPT?

While national pipe taper (NPT) fittings can form a seal, society of automotive engineers (SAE) fittings require an O-ring or a gasket to create a seal. SAE fittings are reusable and often utilized in low pressure applications such as refrigeration and automotive systems. SAE fittings can be male and female, both of which feature a 45-degree flare seat. Meanwhile, NPT fittings can be used to make a close seal. Nevertheless, polytetrafluoroethylene tape or a sealant should also be used to ensure that the seal is free from leaks.

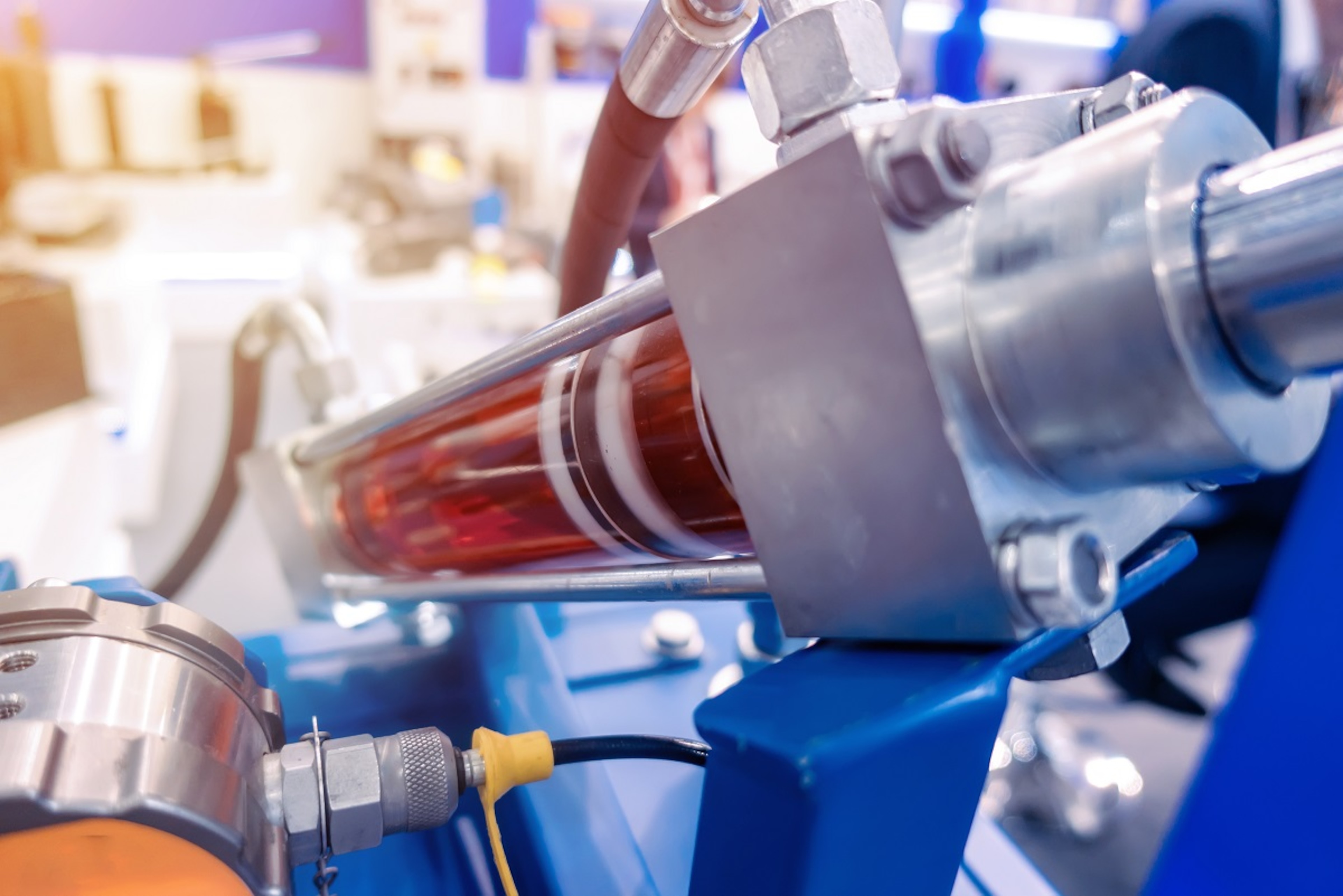

What are hydraulic couplings and hydraulic quick release couplings?

Both hydraulic couplings and hydraulic quick release couplings are used to connect hoses and fittings in hydraulic systems. Made from materials such as brass and aluminium alloys, they are often capable of withstanding high pressures. There are two main types of hydraulic couplings: traditional hydraulic screw couplers and hydraulic quick release couplings. They can both be used as hydraulic pipe fittings and usually require additional sealing components such as O-rings. Hydraulic quick release couplings are normally used in systems that require frequent connections and disconnections to a fluid line.

What are the different sealing methods for hydraulic fittings?

Hydraulic fittings come in many different shapes, sizes and thread types. The most popular hose fittings are O-ring, threads and mated angle. O-ring hydraulic fittings come in three different designs including the O-ring flange, the O-ring boss and the flat face O-ring seal. Threaded hydraulic fittings are either male (threads on the outside) or female (threads on the inside). When the male and female threads are connected, they deform to make a tight seal. Mated angle hydraulic fittings feature angle seats and parallel or straight threads. When the male and female threads are connected, they do not automatically form a seal but bring together the angle seats to form a seal.

Pages you might be interested in

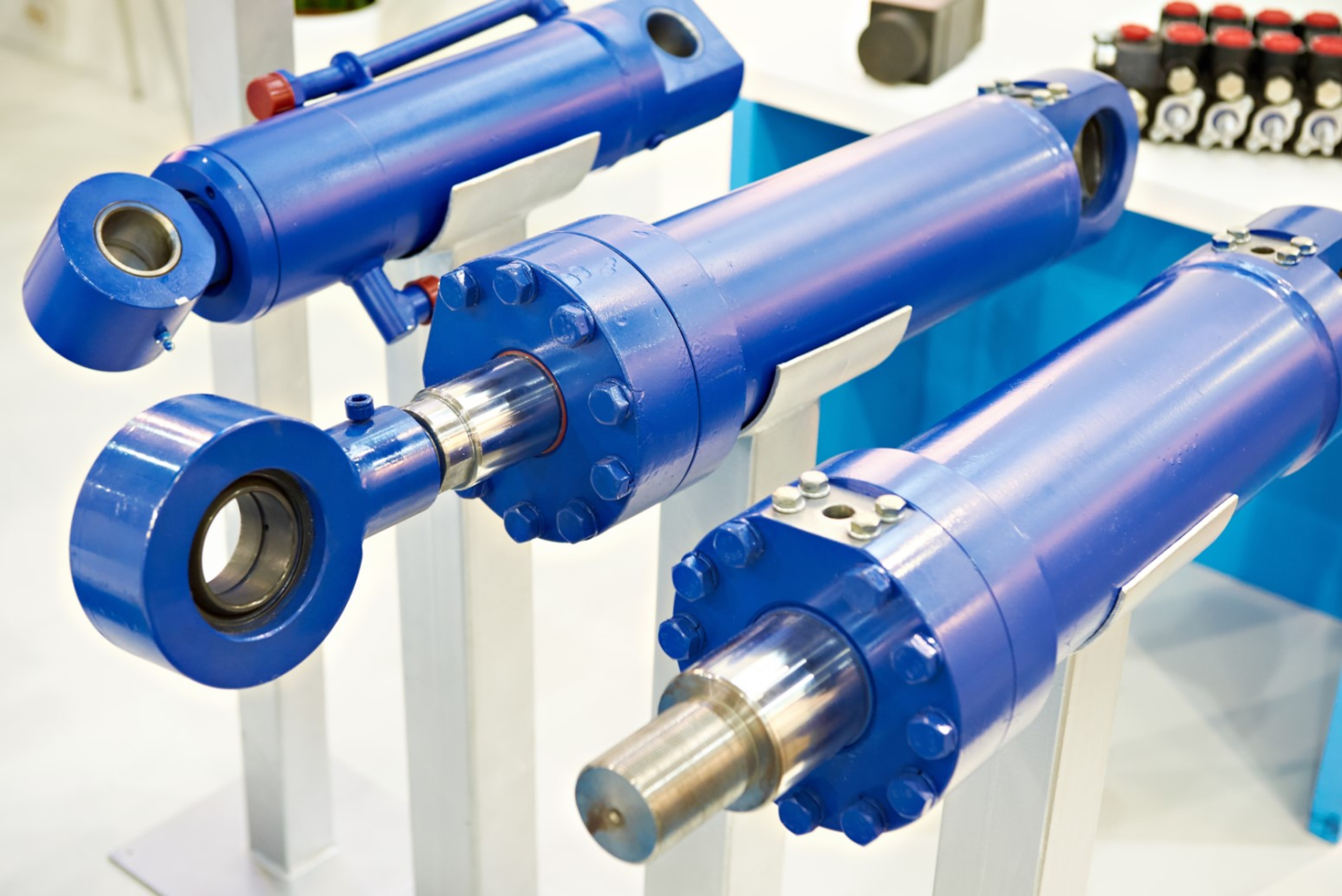

Visit our pages on hydraulic pumps, cylinders, couplings, hydraulic hoses and hydraulic valves