A Guide to Grease Guns, Nipples, Pumps and Connectors

Flowtech

Grease guns, grease pumps, grease nipples and grease connectors are common tools and accessories generally used in manufacturing plants or shops.

Grease Consistencies

When it’s not possible to use oil in applications, grease is the most common lubricant. Often, oil isn’t suitable due to the risk of drips affecting the equipment or the workplace. Grease is a non-liquid lubricant that combines soap and oil. Therefore, it provides higher viscosity levels as an alternative to oil, with a range of consistencies.

Grease pumps are versatile in order to work with the range of grease consistencies and grease points in industrial environments. It’s important to size the pump for specific applications, as grease points can require varying levels and consistencies of grease.

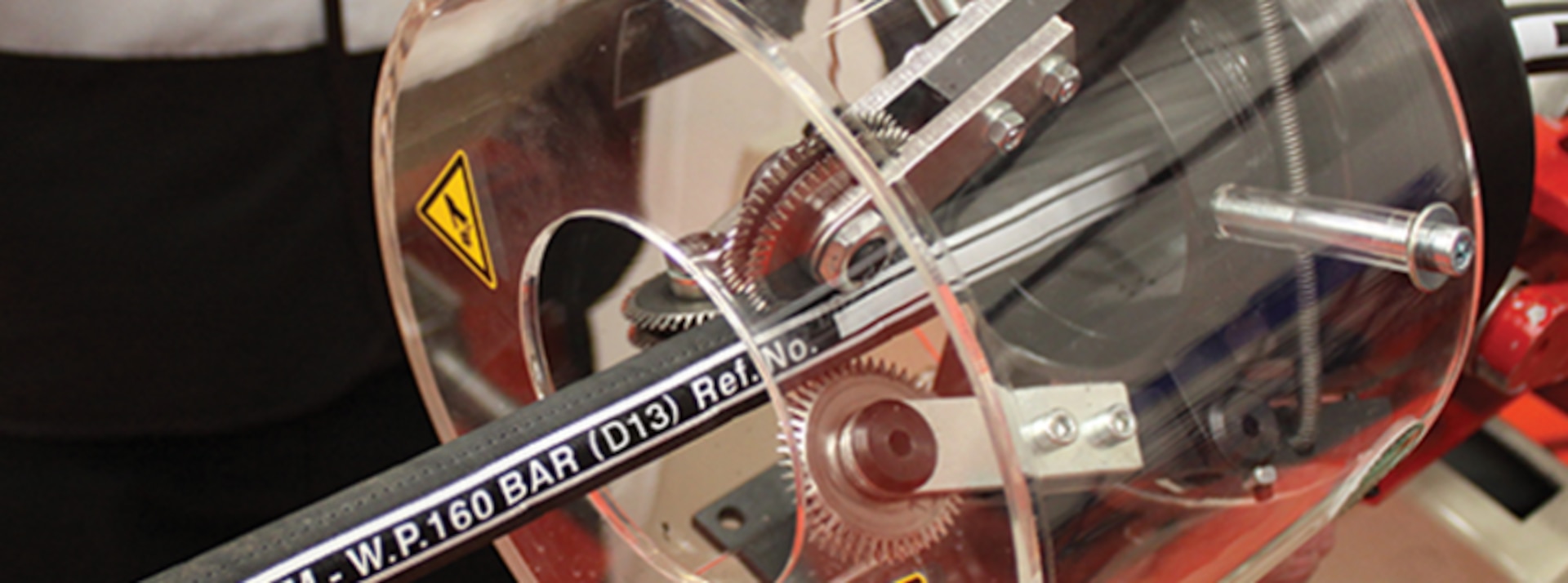

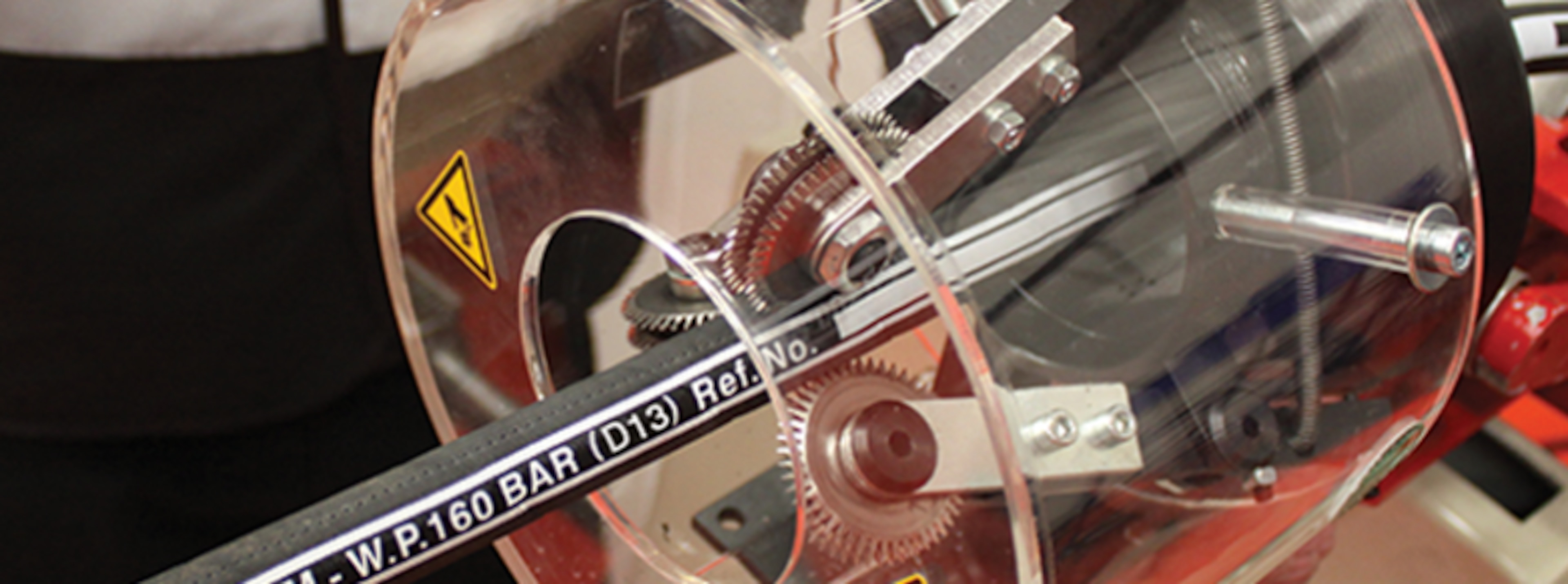

Grease Pumps

Used for commercial equipment, a grease pump is part of a lubrication system. It’s designed to apply grease to a single point or multiple grease points. As a general rule, grease pumps are used in automotive applications and in manufacturing. Large machines hold up to 400 pounds of grease, while smaller grease pumps hold a few pounds.

Benefits of Grease Pumps

In terms of lubrication pumps, grease pumps offer a wide range of benefits:-

Quick Grease Application

Grease pumps save time in the workshop, as opposed to using grease guns that require the manual application of grease to a variety of areas. Grease pumps offer a multi-point central lubrication system that applies exact amounts to the required areas.

Maximum Holding Capacity

It’s possible to store up to 400 pounds of grease with grease pumps. This way, the reservoir is available to use across a significant amount of time.

Economic Performance

After investing in a system that uses a grease pump, the investment pays off quickly. It’s a cost-effective option that saves time with regard to manual labour. It also ensures less grease is used in routine operations.

Additives

It’s possible to add oxidation inhibitors and anti-wear agents to grease with a centralised system. These beneficial additives work to extend the shelf life of grease while minimising abrasion with regard to equipment.

Grease Guns

As a common tool, grease guns are used regularly in manufacturing plants. With a variety of components and applications, most industries use multiple types of grease guns. It’s important to learn about best practices to avoid cross-contamination and incorrect output measurements.

Grease guns come with a variety of grease connectors, couplers and adapters. Choose a flexible hose or a fixed tube to suit a machine's grease-fitting type. For example, it’s best to choose flexible hoses for locations that are hard to reach.

Types of Grease Guns

Grease guns are powered by electricity, hand or air. It’s possible to choose a pistol grip or a lever. Types of grease guns include:

- Manual Lever: with grease forced through an aperture via hand pumps.

- Manual Pistol grip: for a one-handed pumping method.

- Pneumatic Pistol Grip: using compressed air directed into the gun with a hose.

- Batter Pistol Grip: using compressed air with a low-voltage.

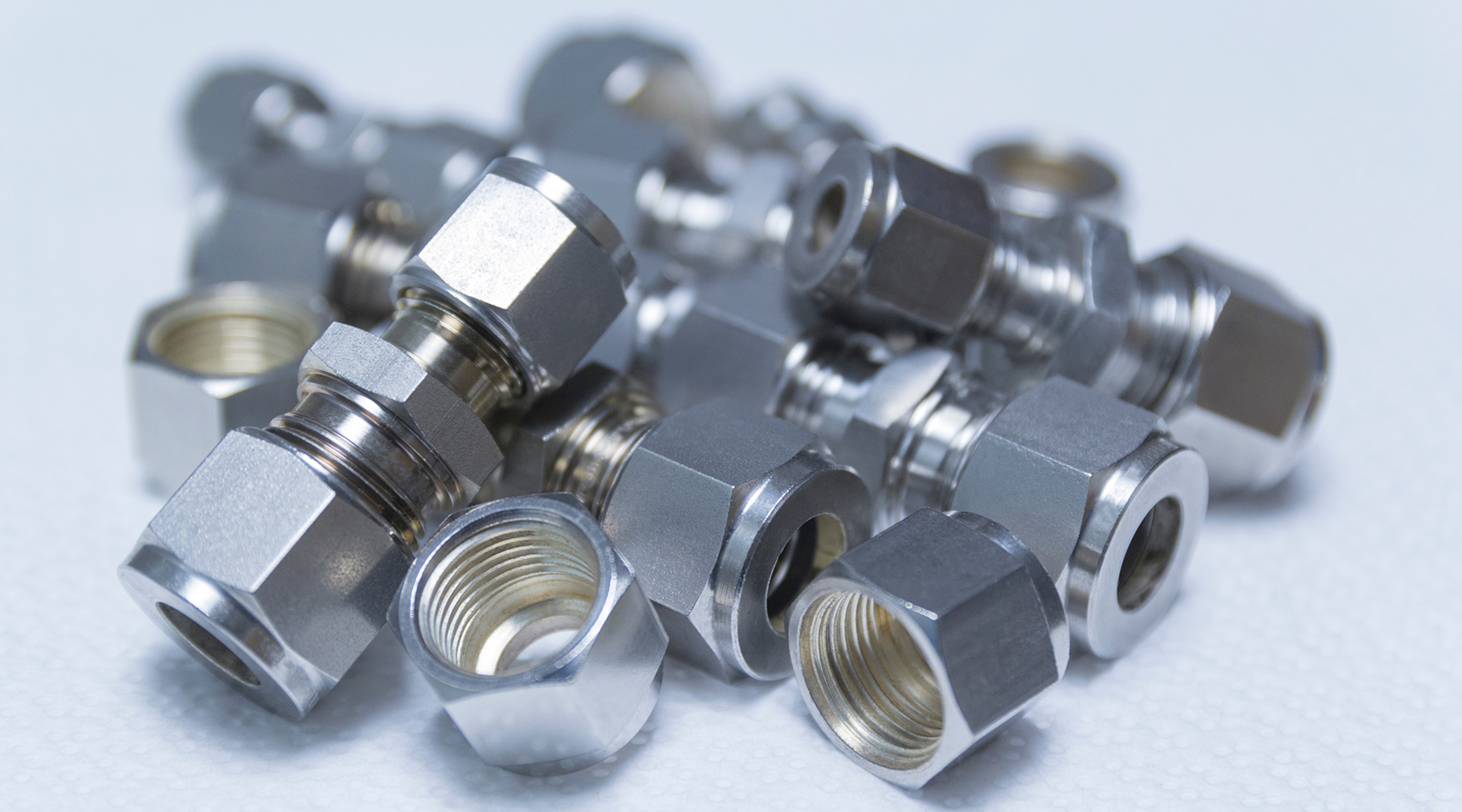

Grease Nipples

Grease nipples are grease fittings that enable lubricant to be dispensed to specific areas when using a grease gun. This type of fitting is a screw-on metal valve cap. It features an aperture on the top and a channel behind the opening. In the voids of a bearing, the channel runs to a specific area where the lubricating grease is required.

The main use for grease nipples with grease guns is to ensure that lubrication reaches areas that are difficult to reach otherwise. The process is neat and easy, without the need for messy clean-ups after application.