SERVICES

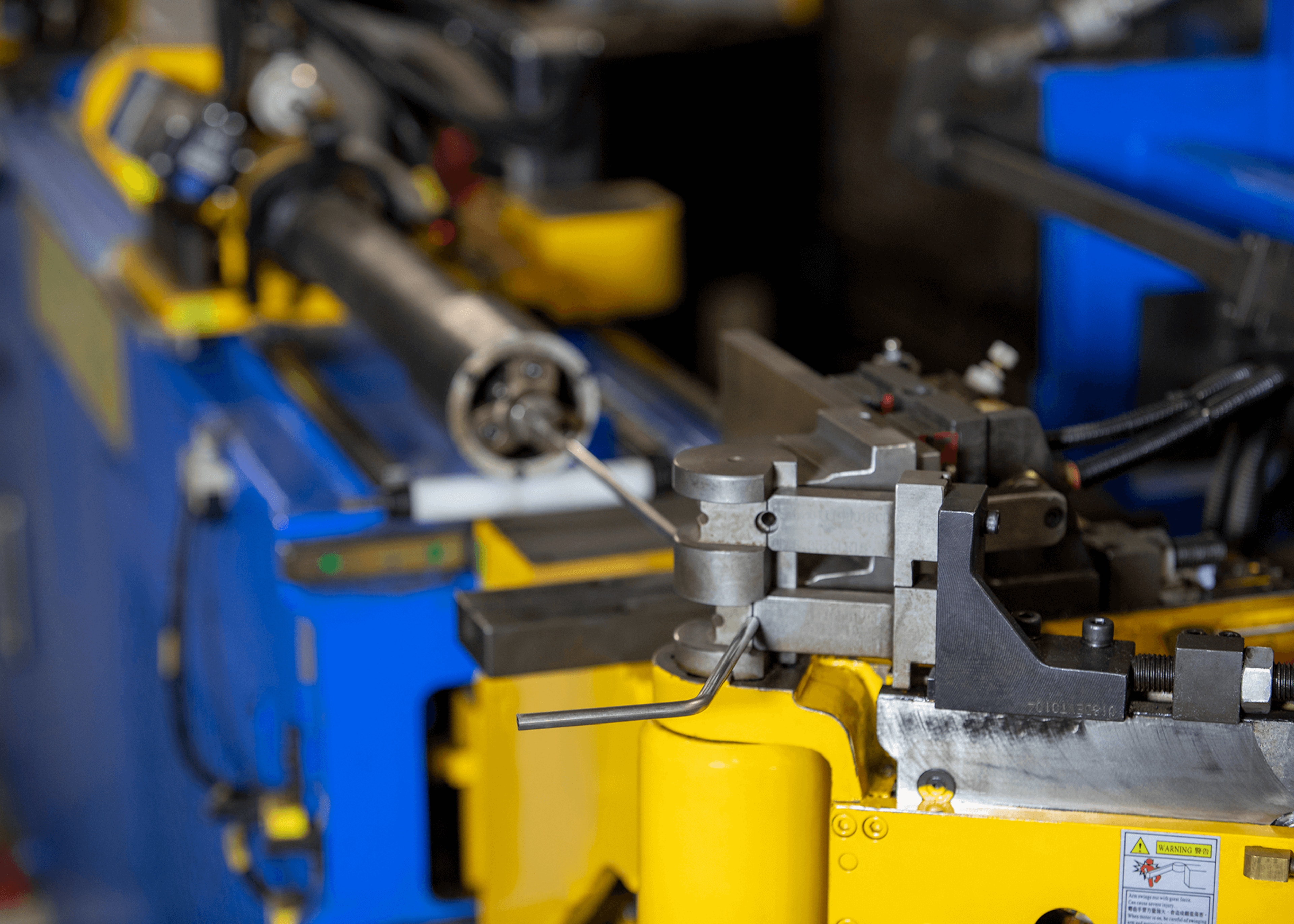

Tube Manipulation

Domestic and industrial settings call for tube manipulation in many tasks including hydraulic system builds, refrigeration and heating. Our tube manipulation service, combined with Walform ended tubes are used in countless applications for many industries.

You design it, we create it

Our experienced team are well-equipped to deal with tube manipulation on many materials such as copper, brass, mild and stainless steel. They deliver precise requirements and replicate designs from your drawings or samples, besides offering on-site support and advice.

We offer tube manipulation in conjunction with:

- Tube bending

- Tube end forming

- Tube swaging

- Tig welding

Our capabilities

Efficient and precise results

Our use of advanced equipment mean the process is efficient and the results are always precise.

Different materials

Tube manipulation available for materials such as copper, brass, mild and stainless steel.

Fully automated

Precise specifications and larger quantities can be produced due to automated machinery.

Additional services

Can be used in conjunction with bending, end-forming, swaging and tig welding.

Produced on demand

We also have the capabilities to provide fully automated tube manipulation, allowing for precise specifications and larger quantities to be produced on demand.

- Electronic 3 axis CNC precision bending machines

- 300 tube single run (max length 700mm)

- Tube manipulation from 6mm to 20mm

Walform Tube Forming

Do you or your engineers believe a tube fitting is sealed correctly because it just 'feels right'? You're not alone, it's a common mistake that often means nuts are over or under-tightened. The result is often avoidable leaks, loss of pressure and tube failure, not to mention an unsafe working environment.

Our Walform system outstrips guess-work and traditional heat manipulation methods. Using a conventional DIN fitting body and a DIN nut, it guarantees an absolutely leak-proof seal. Compared to other cutting-ring tube fitting systems it uses a lower tightening torque that cuts assembly times and gives total reliability.

Want to find out more?

Get in touch with our Flowtech engineers to find out more about our tube manipulation service, and how we can help you.