Our Capabilities

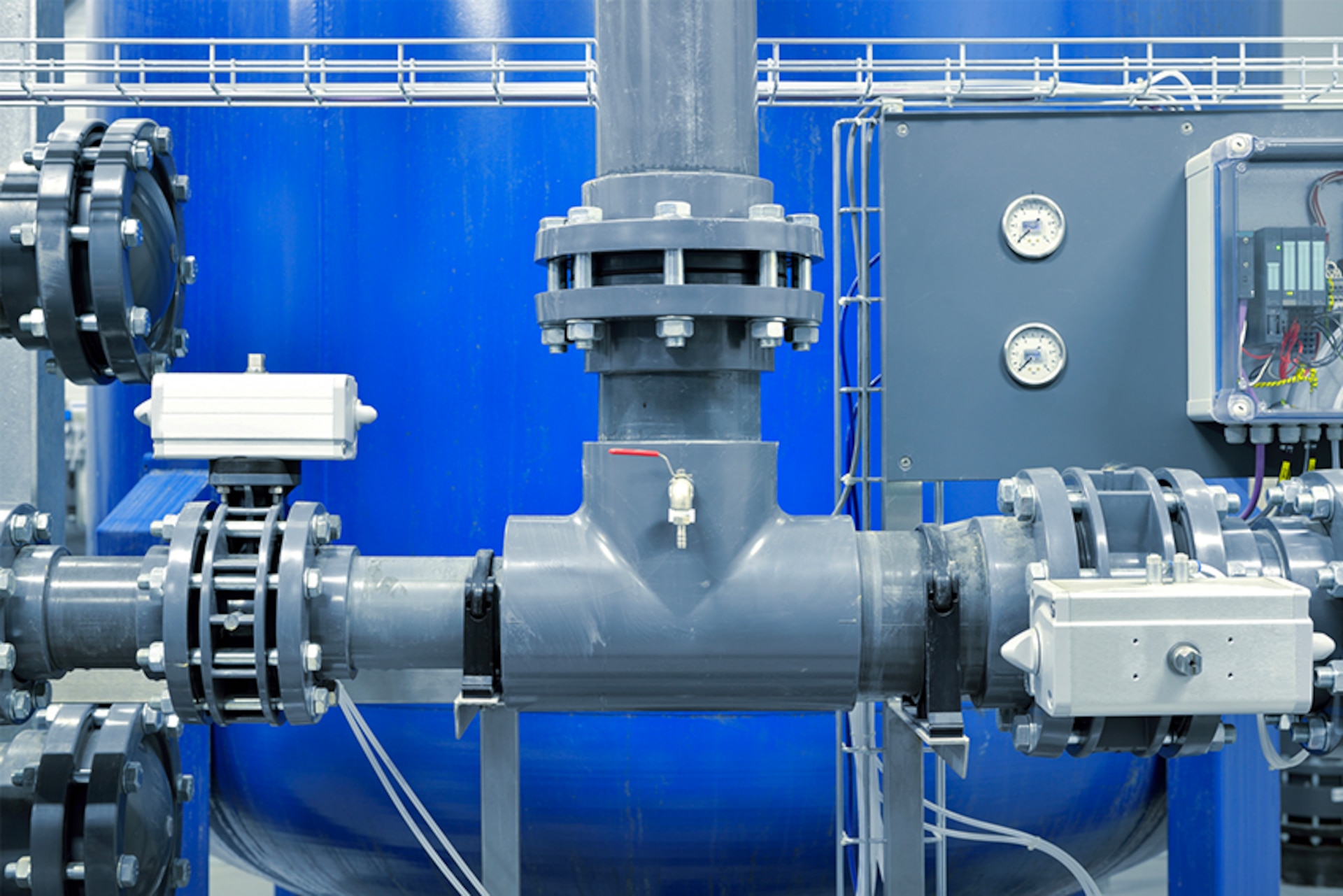

Maintenance

Our Flowtech engineers are able to supply a suite of servicing options, from system health checks to oil analysis and management.

Quick Enquiry

Our capabilities

Compressor Servicing

Our engineers can help improve your compressed air and fluid processing solutions, as and when required, including on-site compressor repair and maintenance.

System Health Checks & Diagnostics

With a system health check, our engineers often discover that systems are energy inefficient, whilst our diagnostics help determine the improvements that will lead to direct cost savings.

Oil Analysis & Management Programme

With the most up-to-date equipment, our team of service engineers are ready to provide you with oil analysis and ongoing oil management advice.

Parts Servicing

As well as servicing parts brought into our ESCs, we also service and repair fluid power equipment on site, from planned preventive maintenance contracts, and maximising machine up-time to emergency repairs.

Compressor Servicing

When it comes to utility efficiency loss we know that compressed air is a chief culprit. In the age of energy efficiency and in the pursuit of savings, just a couple of corrective actions can set a business on its way to reduced compressed air energy costs.

A variety of industries make use of our compressed air energy solutions, giving them access to previously untapped and sustained energy savings, greater efficiency and a decreased reliance on electrical energy.

Air compressor servicing

Whether you have an emergency shutdown or need a scheduled service performed, we have you covered. We offer monthly, quarterly, annual, and emergency compressor maintenance if required.

Our service team has decades of service experience and can work on all rotary screw, piston, and reciprocating compressors including but not limited to Abac, Allup, Ingersoll Rand, Kaeser, HPC, Atlas Copco, and many more.

System Health Checks

We all need health checks, from a check-up at the doctor to an MOT on your car; fluid power systems are no different.

Health checks on fluid power systems ensure that critical breakdowns are limited or even eradicated, thereby maximising machine productivity and meeting output targets. Our engineers often discover that systems are energy inefficient, with some of the most common signs being undetected leaks in compressed air systems or clogged up filter elements.

System Diagnostics

Through our system diagnostics, we help determine how improvement to your fluid power systems will provide you with significant direct cost savings.

Our health checks include:

- Complex fault finding

- System design modifications

- Pressure Equipment surveys

- Risk assessment, method statements with full H&S compliance

- Accumulator inspection and repair

- Pressure equipment register

- Inspection and maintenance plan creation

- Full labelling of all systems

- 24/7 access to all hydraulic and lubrication system components

- Talented and dedicated team of hydraulic service engineers

Oil Analysis

Although samples of oil can be taken from the tank, where there is a return filter, this can often give a misrepresentation of the real state of the oil and the hydraulic system. Wherever possible, sampling should be taken upstream of the return filter.

This will provide a more accurate indication of the cleanliness and condition of the oil and the associated additives. Just like a blood test, it provides an important insight into the condition of the components in the system.

Oil management programme

The information oil samples provide can be invaluable and act as a method of predictive maintenance. With further sampling taken around the system, it will help isolated the areas that require close attention and ultimately lead to significant cost saving and preventive in-operation failure.

With the most up-to-date equipment, our team of service engineers are ready to provide you with regular health checks, guaranteeing a longer lasting and healthier system.

As part of our oil management program we provide:

- Consultation – assess and identify the right system for you

- Water filtration – water is by far the most common contaminant in hydraulic systems. Our water filtration process removes 100% water, helping increase the life of the hydraulic system and components within it

- Particle filtration – Remove contamination down to 1 micron (3 absolute)

- Oil analysis reports – We will assess the effectiveness of your filtration and cooling systems, and identify components not performing to their optimal state. This is like an MOT for your hydraulic system

- Improvement plan – Practical suggestions from highly experienced service engineers. They will give expert advice on how to reduce contamination before it happens

Parts Servicing

We work closely with our customers to understand their requirements and can often configure and manufacture parts that will ensure the best solution within the required timescale.

We provide complete fluid power engineering and repair services; whether you require a simple cylinder repair or a complete hydraulic system overhaul, our experienced team of engineers are ready to help.

As standard, we source and supply recognised branded products such as Parker Hannifin, Festo, Danfoss and Norgren. We work closely with customers to understand their requirements, and can often configure and manufacture parts that will ensure the best solution within the required timescale.

All product repairs are visually inspected and dismantled before a detailed quote is provided free of charge (providing the repair is carried out by us) and in the event of your item being beyond economical repair, we can also offer a quote for new.

On-site Servicing

We service and repair fluid power equipment on site, from planned preventive maintenance contracts, and maximising machine up-time to emergency repairs. You’ll find we are able to assist you with your on-site problems, from component replacement all the way to a system overhaul. Our experienced service engineers become an extension of your engineering teams.

Our range of services includes:

- Hydraulic cylinder repair

- Design, build and installation of hydraulic power units

- Hydraulic pump repair and overhaul

- Approved hydraulic hose assembly

- Control volve design and build

Get in Touch

Would you like to find out more about our maintenance options? Get in touch with our expert team of engineers today.