SERVICES

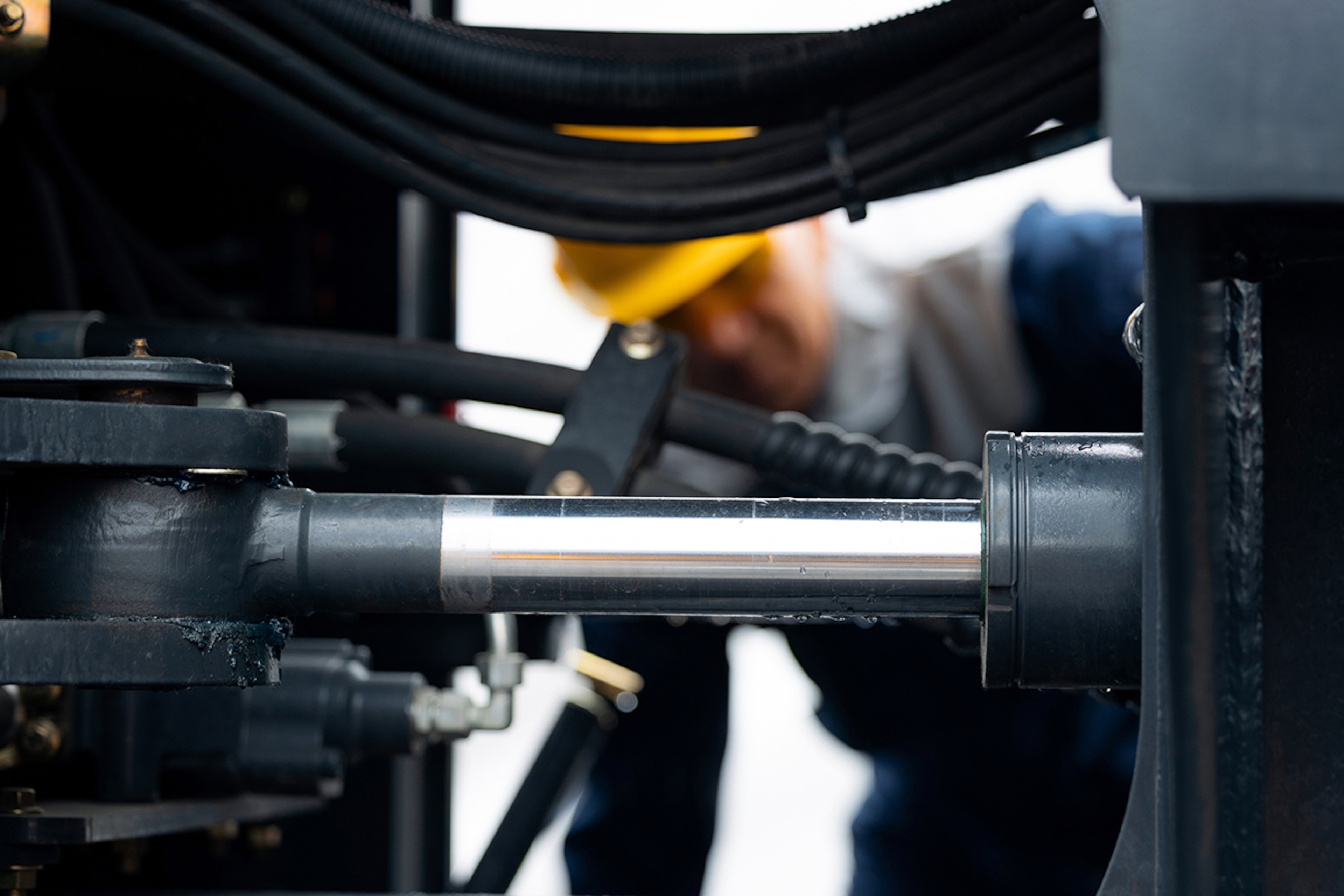

Hydraulic Cylinders

Our service capabilities extend to the design, manufacture and repair of hydraulic cylinders, from smaller options all the way up to large bore cylinders that can weigh upward of four tonnes.

Years of hands-on experience

The ability to deal with customer requirements around hydraulic cylinders comes from years of hands-on experience in applications, design and fault-finding from initial assembly all the way through to installation.

Hydraulic cylinder enquiries come from all manner of different key industries including Aerospace, Construction & Mining, Transport, Agriculture and Automotive. Applications are far-reaching but have included bridges, slurry gates, factories, crushing units and excavators, to name a few.

Whether it’s stripping cylinders down and replacing seal kits, or building from scratch, our team of engineers are fully capable of handling your requirements from our Engineering Solution Centres across the UK, Ireland and the Benelux.

Our capabilities

Manufactured as new

In many instances, a customer will require a brand new cylinder to be manufactured from scratch as part of a new industrial project.

Bespoke design

Our Technical Design team are able to utilise the very latest 3D CAD software to visualise an accurate representation of your hydraulic cylinder before assembly begins.

Reverse engineer

If you have an existing hydraulic cylinder you need a replacement for, but haven't got any technical drawings or accurate dimensions, our team can reverse engineer a solution.

Repair existing

If you have a broken or faulty hydraulic cylinder, our team will be able to disassemble, inspect and provide a diagnosis report before completing any repairs.

What is the Flowtech solution for hydraulic cylinders?

From bespoke custom built cylinders to reverse engineered and bespoke hydraulic cylinders, Flowtech engineers are available to create various types of constructed cylinders:

- Bolted construction

- Welded construction

- Tie-rod construction

We build cylinders to customer requirements and work with selected manufacturers to ensure that quality assurance is guaranteed, with bolted cylinders conforming to ISO 6022 and tie rod cylinders conforming to ISO 6020/2.

Manufacturing new or bespoke designed hydraulic cylinders

Bespoke or custom-built cylinders are designed utilising the latest 3D CAD packages, machined utilising CNC machinery and then hand built, tested, and certified at our Engineering Solution Centres to suit specific needs of the end use and application.

Consideration is made in material choice and components to provide exceptional life and reliability from your new cylinders.

If, however, you have an existing cylinder and would like a duplicate/replacement but do not have drawings for manufacture, we can reverse engineer a solution to meet your needs.

Our Engineering Solution Centre will strip down your existing cylinder and capture all the key dimensions to replicate a new cylinder to meet your fit, form and functional requirements.

Repairing existing hydraulic cylinders

Our Engineering Solution Centre can also repair faulty or broken hydraulic cylinders, where they can be properly serviced and returned to previous functionality, rather than going to the expense of manufacturing a replacement from scratch.

The Engineering Solutions Centre will strip down and inspect your cylinders. Following this, a report will be compiled of the necessary repairs and a quote will be sent out for approval.

Once the purchase order has been received your cylinder will be repaired to operate as new.

Get in Touch

If you would like to find out more about our capabilities when it comes to hydraulic cylinders, get in touch with our expert team today.