Services

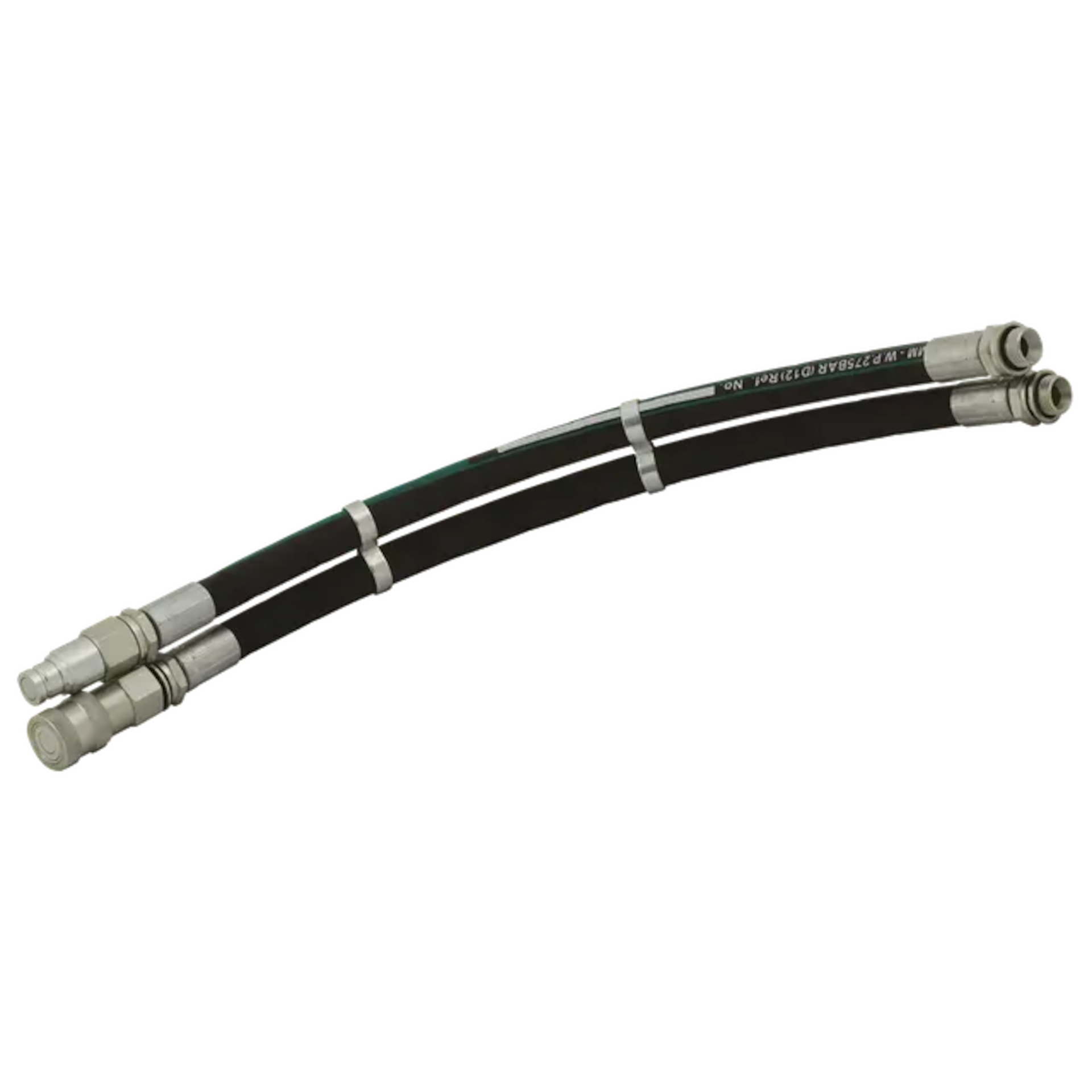

Hose Assemblies

Our Flowtech engineers work closely with designers to assemble products and systems to match specific customer requirements. This includes our advanced hose assembly facilities, which allow us to deliver complex specifications and quantities, depending on the requirements of a particular project.

Quick Enquiry

Experts in Custom Hose Assemblies

Quickly get your equipment up and running with our custom made hoses, from hydraulic hose to jet wash hose. Our efficient hose assemblies will save time and money in the long term, by freeing up your staff for other essential tasks while we remove labour costs and supply reliable assembled products.

Our experienced hose assembly team provide UK manufactured hoses for next-day delivery. From 1 wire to multi-spiral, layflat to MDS with various termination options.

We band hoses up to 8" with crimping available for the following sizes:

- Hydraulic 1/4" to 3" ID

- Industrial 1/2" to 8" ID

- Pneumatic 1/8" to 6"

We also provide a variety of tagging options, protective spiral guarding and collective wrapping on request, for hydraulic, pneumatic, layflat, suction hose, PVC and jet wash. Hydraulic hoses can be colour-coded for easy identification.

Our capabilities

Automated cutting

Our facilities are well-equipped with automated machinery to ensure precise assemblies can be constructed.

Certified hose cleaning

All of our hose cleaning is performed to match current NAS/ISO standards.

Full traceability

Stamping is available for full traceability, as well as ferrule and hose identification.

Colour-coded sleeves

Different coloured sleeves available on request.

Pin-pricked hose assemblies

It can seem counterintuitive to have holes in something that needs to be pressurised. Even so, those tiny holes or pin-pricks, actually help keep the hose in good condition and extend its lifespan.

The tiny pin-pricks only puncture the tube's outer cover. So, the gases that gradually build-up between the tube and the cover can escape. This prevents the hose from becoming blistered or bubbled, improving its reliability and life-time.

How is pin-pricking done?

A wheel passes along the hose as it's pulled from the mandrel – pricking the cover in a series of uniform punctures that stop at the reinforced layer.

For hoses ranging from 11.5mm to 85mm Ø OD, our hose pricking equipment guarantees the hose is perforated at the correct tolerance.

Our pin-pricked hose comes in:

- Full coils

- Bespoke cut lengths

- Fully assembled

- All pin-pricked hoses arrive with you, clearly labelled so you can easily identify them from standard hose

Popular Hose Assembly Products

Shop Our Full Offering of Hose Assemblies

Get in touch

Would you like more information on our hose assembly capabilities? Get in touch with our Flowtech engineers today.