What is a Hydraulic Motor?

Flowtech

An overview of Hydraulic Motors. What they are and how they work.

If you’ve ever operated any type of machine, you’ve likely come across a hydraulic motor. Hydraulic motors can be found in almost every piece of machinery, and are one of many vital components that make the equipment work how it should do.

The role of a hydraulic motor is to provide the force and motion needed to move an external load. They can generate substantial power and are typically used in any application which requires constant speed variations with a slow or quick rotary movement.

In this article, we will provide an overview of exactly how hydraulic motors perform these functions and the difference between the types of motors.

How hydraulic motors work

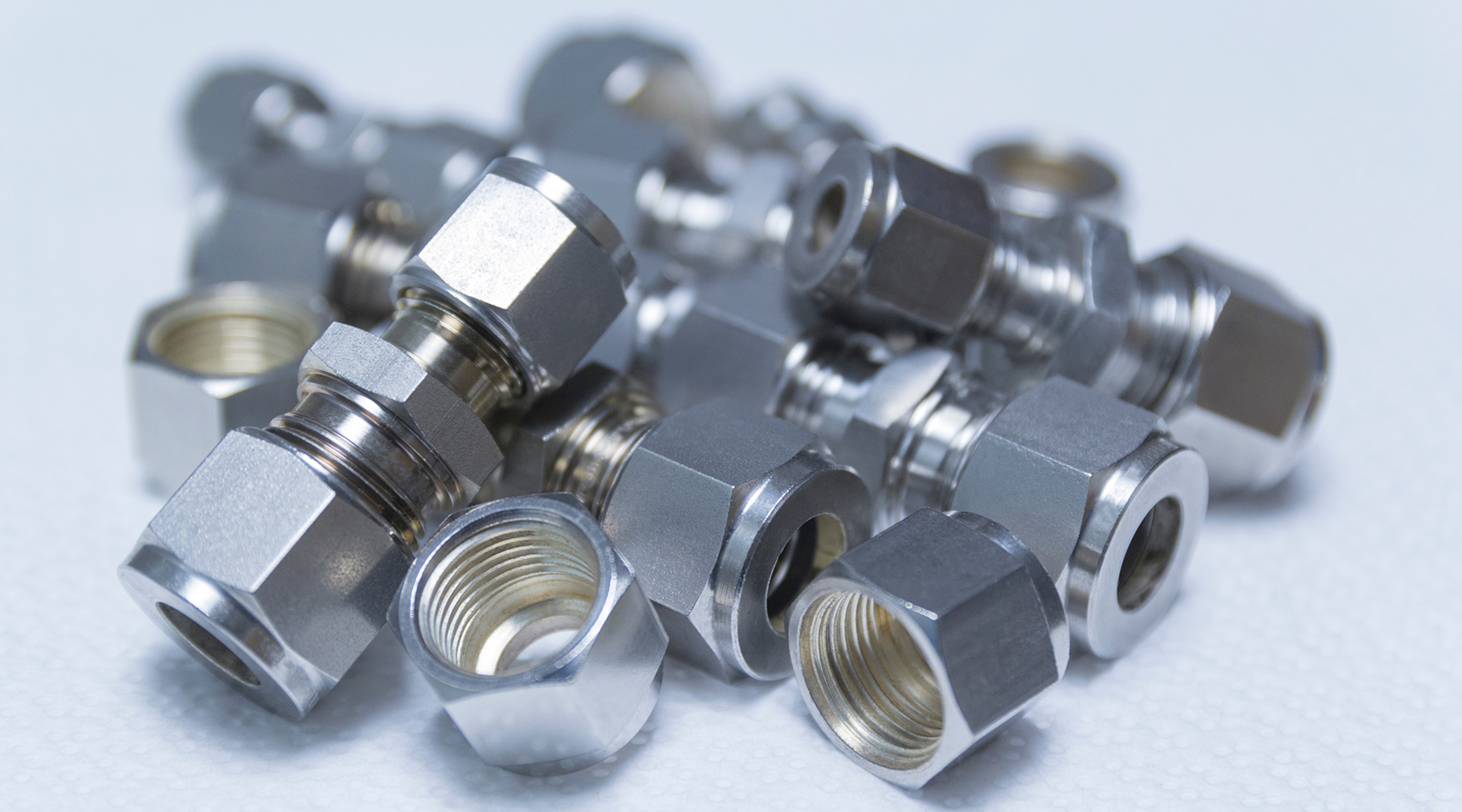

Hydraulic motors are essentially mechanical actuators that work to convert fluid power into the mechanical energy needed to power a machine.

Fluid power is the driving force behind all hydraulic operations, including the way motors work.

Hydraulic motors use pressurised fluids from the hydraulic pump to generate force such as angular displacement and torque. As the fluid is carried to the hydraulic motor, it pushes on the gears, vanes or pistons of the motor and as a result, turns the motor output shaft.

The rotating shaft uses flow and hydraulic pressure to create rotation torque, therefore generating the power and force needed to move the external load. Then the cycle repeats.

The speed at which a hydraulic motor operates is dictated by the amount of oil and pressure supplied by the pump.

What are hydraulic motors used for?

Hydraulic motors play a vital role in our day-to-day lives, and the need for them is ever-growing. They can be found in a wide range of applications across a broad spectrum of industries including construction, agriculture, manufacturing and production.

Designed to be robust and heat resistant, hydraulic motors can withstand extreme environmental conditions such as excessive heat and submersion. This makes them particularly suitable for industrial applications such as conveyors, mixers, drilling rigs and so on.

Hydraulic motors are a great alternative to electric motors in mobile applications where power without access to electricity is required. Due to their ability to provide incredibly high torques in a compact design, they can typically be found powering tracked vehicles such as bulldozers and excavators.

The different types of hydraulic motors

There are four main types of hydraulic motor, all with one or more sub-type. Each motor type has different characteristics, making one more suitable for certain applications than another.

The different types of hydraulic motors are characterised by their:

- Maximum operating pressure

- Maximum rotational speed

- Displacement (fixed or variable)

- Constant peak and power

Here are the most common types of hydraulic motors.

Gear motors

Gear-driven hydraulic motors have two sub-types; gear (slow speed) and epicyclic gear (high speed). They comprise two gears – the idler gear and the driven gear which rotate against each other and adapt to negative and positive rotation due to their symmetrical design.

By design, gear motors are compact, lightweight, and easy to maintain with a good oil suction capacity and impact resistance. On the other hand, they typically have a low starting torque, relatively low volumetric efficiency and input pressure which makes them most suitable for high speed, low torque applications.

Displacement volume in gear motors ranges from 3 to 100cc, and they can typically reach a maximum torque of up to 400 Nm. Depending on the model, speeds range from 500 to 4,000 rpm and maximum pressure can reach 250 bar.

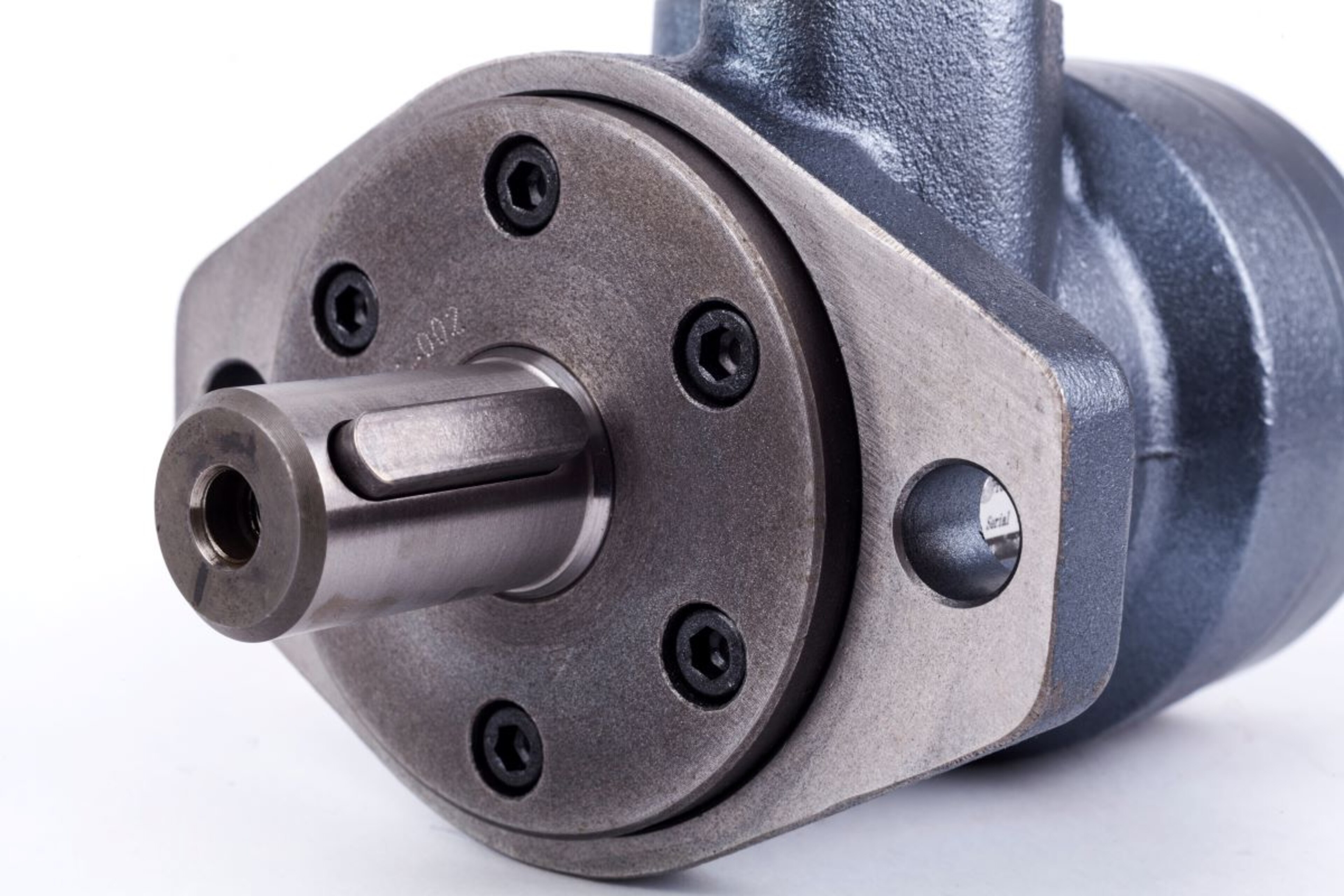

Orbit (Gerotor/Geroler) motors

Orbit motors, or Gerotor/Geroler motors, can produce large torques at very slow speeds and operate on the orbit principle.

The principle is based on an internal gear motor (rotor) rotating within a fixed external gear (stator). The motors are fitted with teeth and lobes, with spaces in between them for pressure chambers.

As the pressurised hydraulic fluid flows into the chambers it creates an imbalance of pressure, generating a torque which is transmitted by the internal gear to the motor’s output shaft, causing it to rotate (orbit).

Compact in design, Gerotor and Geroler motors are typically very well suited for use in mobile applications and are used across a wide range of industries including construction, agriculture and material handling. They can deliver from 10 to 50,000 psi of torque with operating speeds of up to 2,000 rpm.

Vane motors

Vane motors are simple in design, consisting of a housing with an eccentric bore and a rotor with vanes. The pressurised fluid creates an unbalanced force on the vanes, which causes the rotor to spin in a single direction, either clockwise or counterclockwise.

Vane motors are small in size and particularly suited to vertical installations. They offer high torque at low speeds, stable operation, balanced flow, high input speed and low noise level.

Maximum pressure in vane motors can reach up to 230 bar, and they can deliver up to 650 Nm of torque with a displacement volume of up to 214cc.

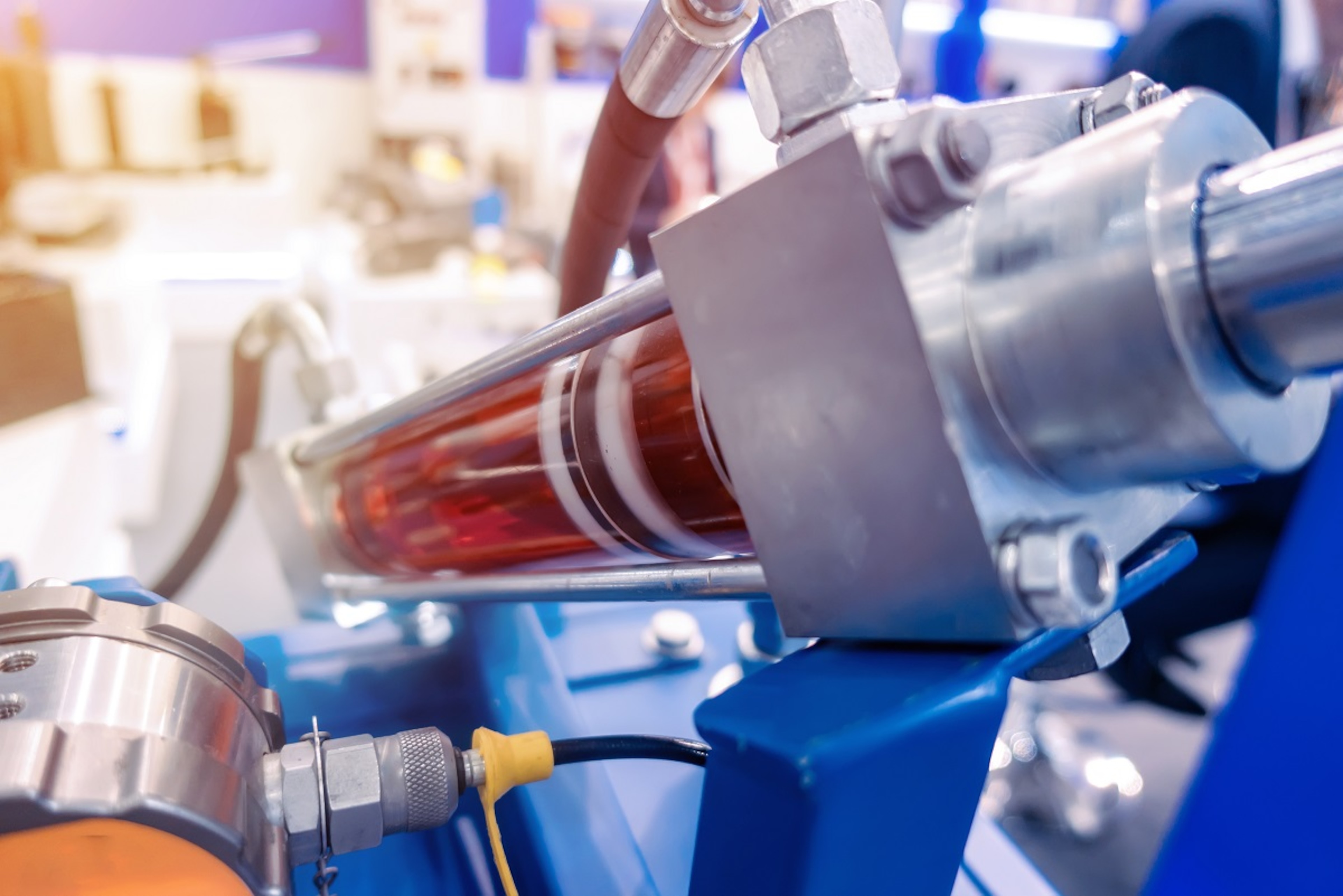

Piston motors

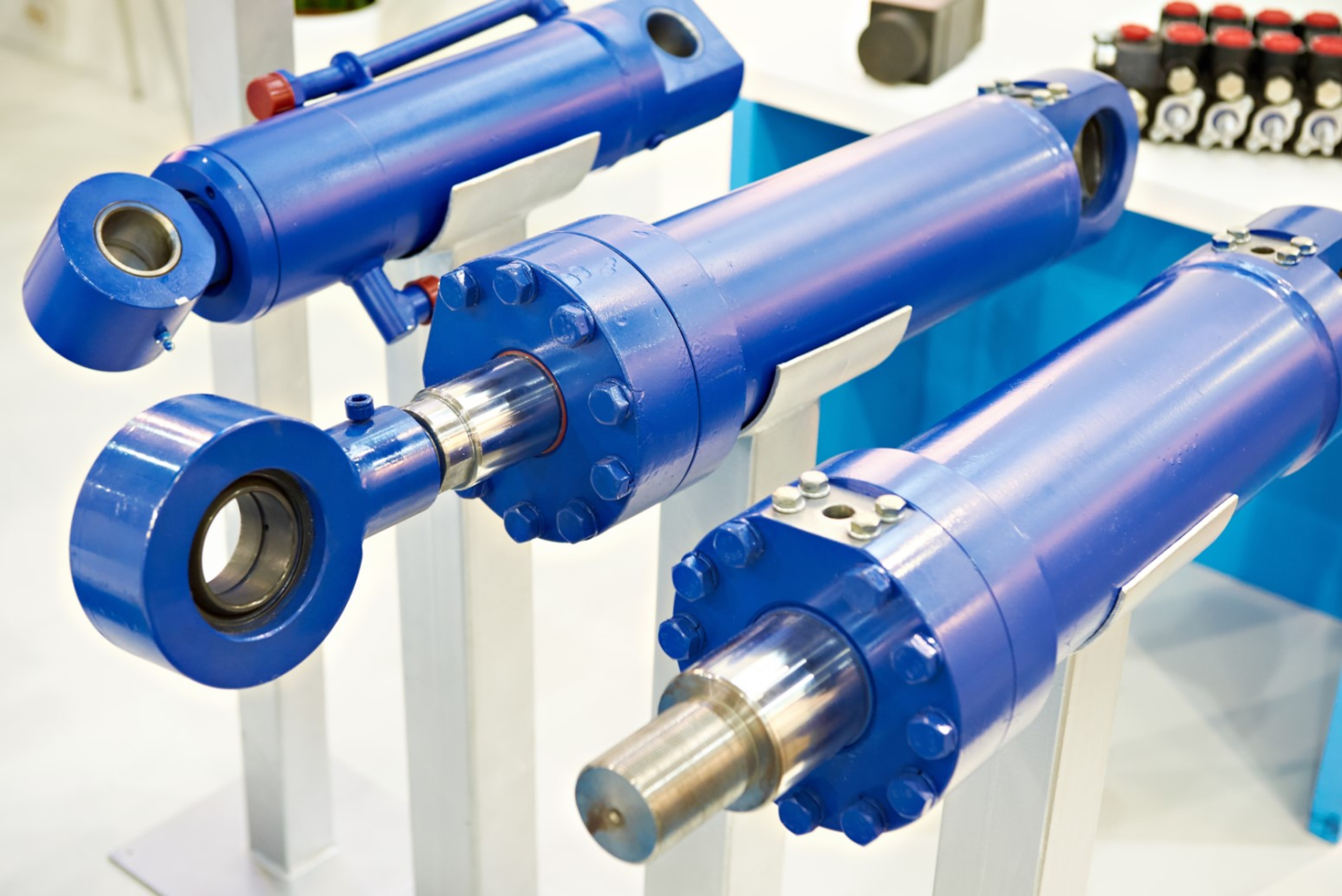

Piston motors are available in two types; radial piston motors and axial piston motors.

Radial piston motors are low speed and high torque, capable of generating a far higher torque than axial piston motors. Here, the pistons are arranged perpendicular to the axis of the crankshaft and they move in a linear motion, which is then converted to rotary motion.

Axial piston motors generate a lower torque but have a higher speed range. In this type, the pistons are arranged in a circular pattern with housing that rotates about the axis by a shaft.

In general, piston motors are suited to applications which require large amounts of power. They can displace liquid from 10 to 1,000cc with maximum operating pressures of 450 bar and speeds of up to 11,000 rpm. Torque is the highest of the three motor types, capable of reaching over 10,000 Nm.

Selecting a hydraulic motor

Choosing the most suitable hydraulic motor for your application is crucial to ensuring optimal efficiency. If you’re not familiar with motor selection, we can help.

Flowtech can supply a range of hydraulic motors from leading manufacturers. We can also offer in-house modifications or custom builds to your exact specification. If you’re looking for help with choosing the right motor, get in touch with us.