Case Study

Train Cooling System

Our latest challenge was given to us by a rail operator with an out-of-date cooling system that drastically needed modernising, to ensure that train staff would be able to remotely adjust the temperature of operational carriages.

Summary

Location

Wales and Scotland

Industry

Transport

Product area

Hydraulic Cooling System

Service area

Advanced Design & on-site technical support

Challenge

Many cars within the rail sector are equipped with a dated Waxstat-operated cooling system that can be inherently unreliable. When the engine reaches its optimum operating temperature, the thermostat opens and releases coolant to the Waxstat, which in turn melts the wax. Once the wax melts, a hydraulic pilot signal is released and closes a bypass valve within the hydraulic motor that drives a fan. Due to the on/off functionality of this system, it puts a high demand on the various components and therefore reduces its efficiency and reliability.

Concept

Upon investigation, our experienced engineers proposed an innovative electro-hydraulic solution. The concept was to replace the current Waxstat with an electro-hydraulic proportional fan drive system, consisting of a kit of parts including wiring, hose assemblies, temperate sensors and an electronic fan control system, with the option to integrate a variable displacement pump at a later date for further energy savings.

Solution

Our team has recently supplied the solution to both Arriva Trains Wales and Abellio ScotRail. Before the end of 2018 over 100 cars will benefit from this solution, which is designed for ease of installation and comes with easy-to-follow instructions. Our team has been on hand to ensure the new concept is commissioned correctly.

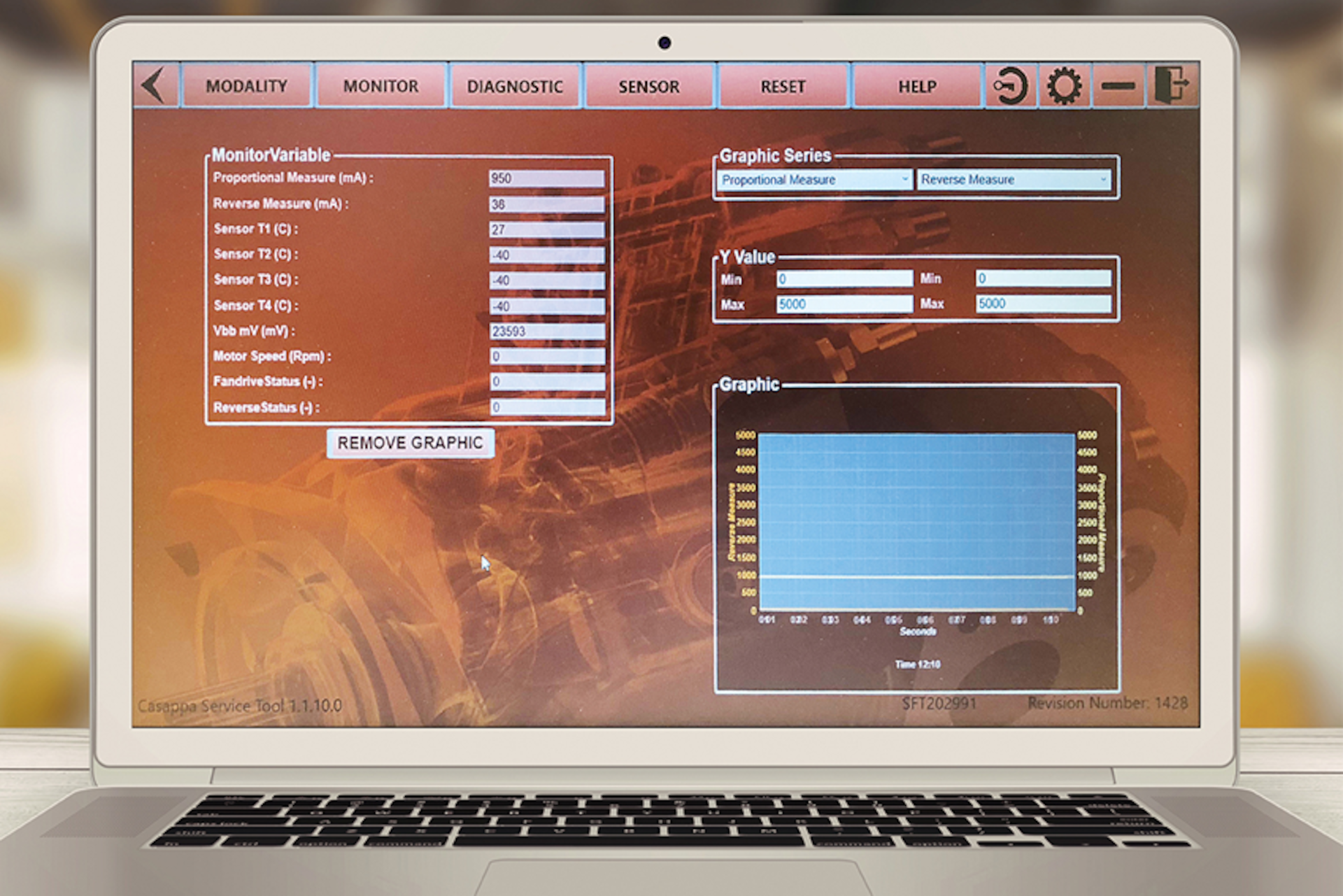

The new electro-hydraulic system provides improved flexibility with live diagnostics data, available via a laptop, which allows engineers to adjust parameters with ease whilst optimising the efficiency of the cooling system. In addition, the solution provides a proportional fan speed and therefore increases efficiency and the life of components.

As a fail-safe, and in the event of damage to the system, the fan is automatically set to run, ensuring that a train’s engine temperature is kept within required limits.

Benefits

- The new system requires reduced pipework and therefore has lower installation costs

- The parts required are supplied in a complete kit, allowing for quick and easy installation and commissioning

- Our team pre-sets the parameters for convenience but these can be easily adjusted if required

- Easy fault diagnosis for a reduction in maintenance time spent on the passenger cars

- The electro-hydraulic proportional fan drive system provides improved efficiency

- The option to use a variable displacement pump would further improve energy efficient and therefore reduce running costs

- Ultimately, a vast increase in the reliability of train journeys, through decreased down time and reduced maintenance requirements

Get in touch

Speak to our expert team to see how we can help you with your next hydraulic system design and installation.