Case Study

London Sewage Tunnels

When we were asked to support on a major project to upgrade a system of sewers in London, our engineers were more than capable of taking on the challenge that came with controlling the flow of a huge volume of waste water.

Summary

Location

London

Industry

Utility, Water Ways, Infrastructure, Waste Energy

Product area

Hydraulic Systems

Service area

Advanced Design & Manufacture

Challenge

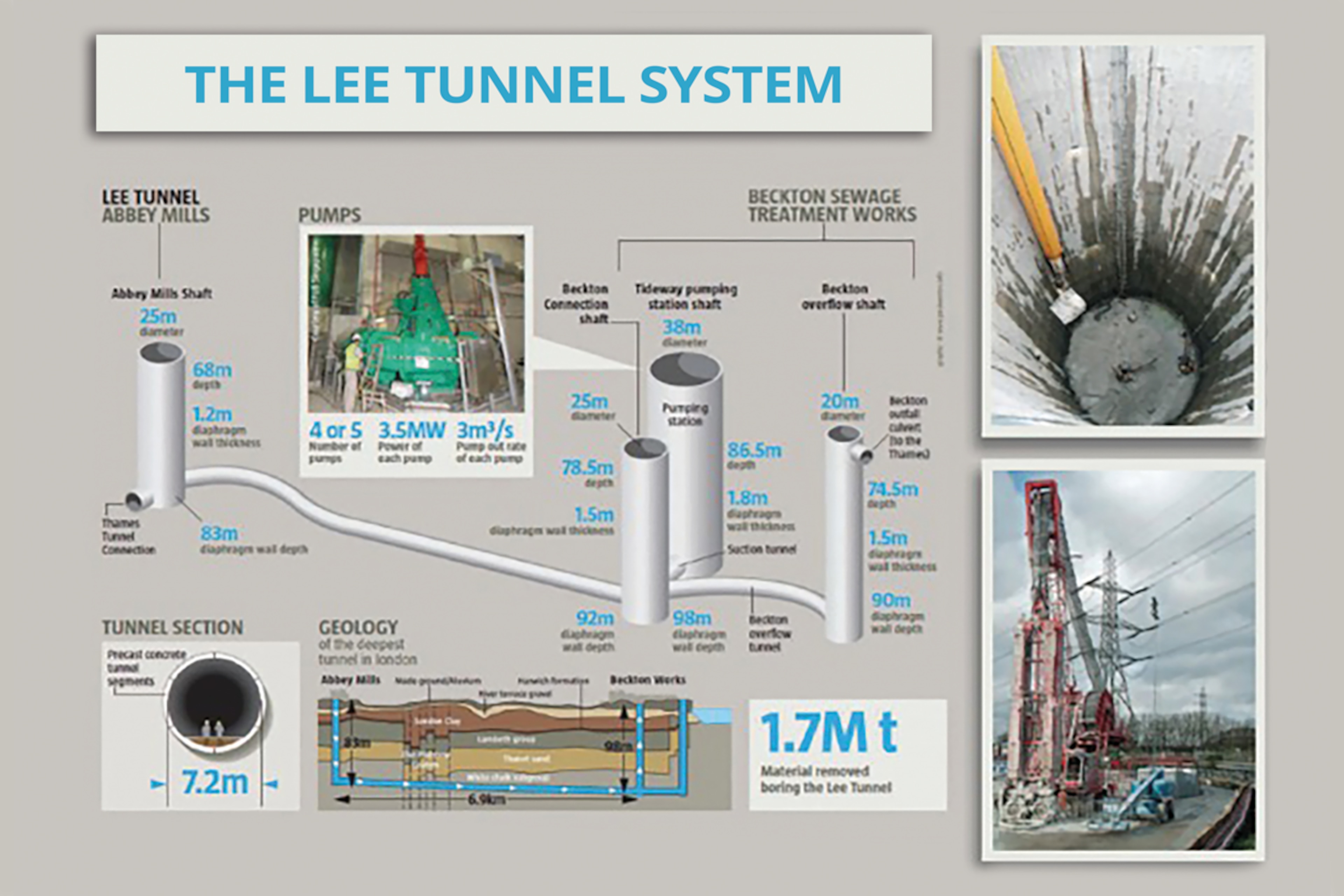

The Lee Tunnels are London’s largest and deepest shafts, and the tunnelling system is required to store 350,000m3 of storm water and sewage, which is pumped out to Beckton STW following each tunnel’s filling event.

As part of a major project to upgrade the London sewer system, the plan was to reduce 40% of the volume of sewage (39 million tonnes per year) flowing untreated into the Thames at Beckton, east of London.

Our challenge was to provide the power and control of a system that would be used to open and close the tunnel gates, allowing easy flow over and control of 16m tonnes of waste water annually.

Concept

The requirement for this project was to design and assemble a complete hydraulic system, capable of controlling the flow of 3 cubic metres of sewage per second throughout the Lee Tunnel System, with an advanced electronic control panel.

Solution

A power pack was designed to provide the strength to open and close the tunnel gates and allow the sewage to flow through the Lee Tunnels. As the project developed, it became apparent that additional engineering and components were required to fully control and power the Thames Valley Sewage Tunnels.

As a result, we were asked to supply the cylinders used to power the gates, manifold blocks and over 1000 metres of piping to facilitate the completion of the hydraulic system.

Benefit

The sophisticated requirements to electronically control the systems resulted in a number of changes to the electrical design. However, following a number of extended days and weekends, the customer requirements were met and this project was delivered on time and on budget.

We were proud to provide cost-effective tailored solutions, delivered on time, which will generate significant environmental benefits and reduce sewage in the Thames (East London) by 40%.

Get in touch

Would you like to find out more about getting technical support from Flowtech? Speak to our expert team today.