Case Study

Electric Drive Shunter

We were tasked with designing an electro-hydraulic power pack that would be able to assist a long-standing customer with improving the efficiency of their rail shunting, to comply with updated emissions regulations.

Summary

Location

Ireland

Industry

Transport

Product area

Hydraulic Power Packs (HPUs)

Service area

Advanced design & on-site installation

Challenge

Unilokomotive Ltd is a long-standing customer who we have worked in partnership with, continuously improving the efficiency and versatility of their shunters. New emission rules and workshop air pollution regulations have now presented a new challenge.

The electric drive shunter concept was created to shunt and move loads of up to 500 tonnes. This machine had to comply with both rail standards and the necessary safety controls in place. This included controlling the speed to as low as 5 metres per minute, failsafe braking coupled with train braking, zero emissions, automatic coupling from the cab and anti-wheelspin.

Concept

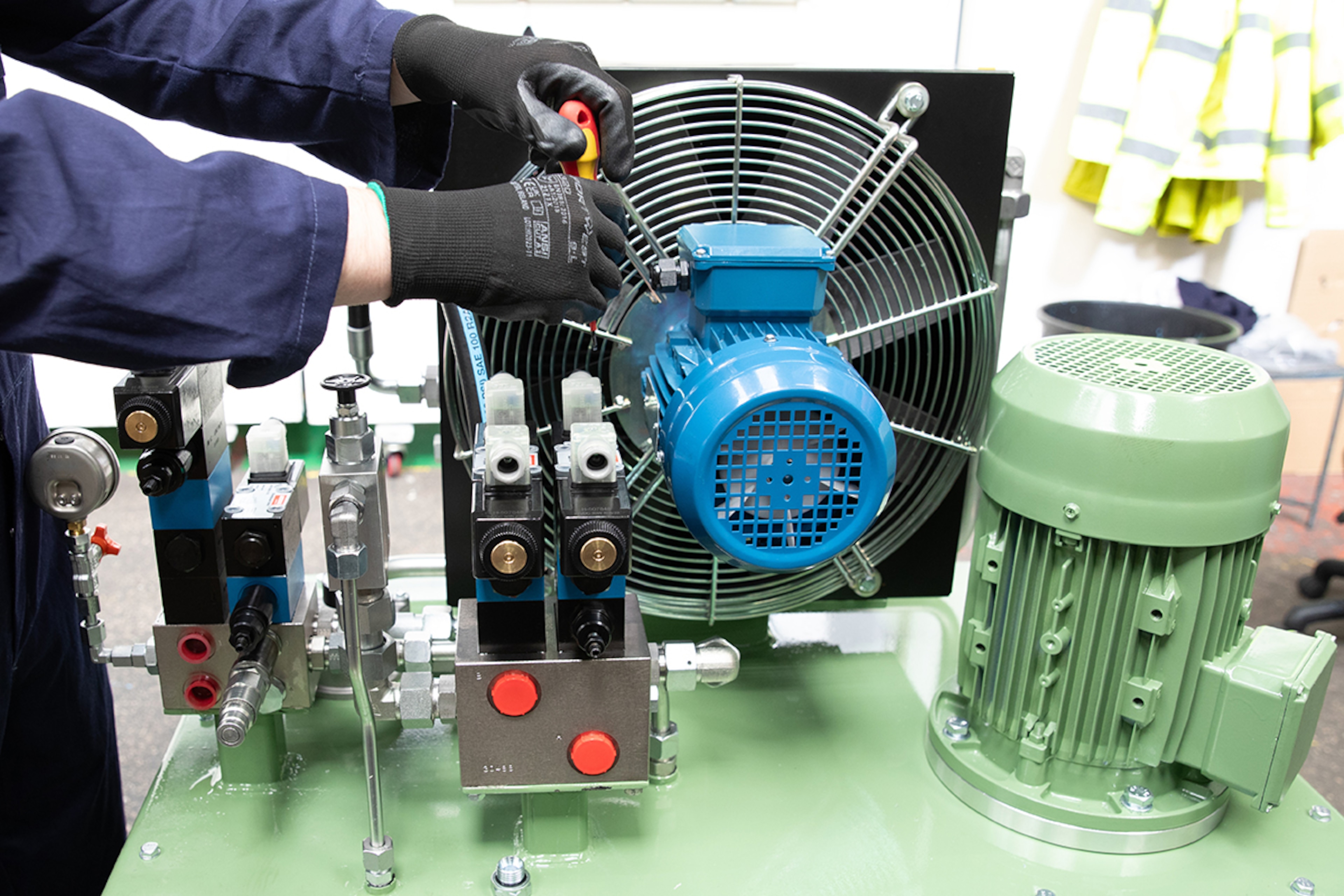

To support the electric drive shunter, we designed an electro-hydraulic power pack, which could be programmed to give various outputs depending on the function selected. The systems would be powered hydraulically to improve the traction control of the machines, whilst allowing shunting of up to 50 times the shunter’s weight. The concept included provision of components that would allow for easy operation and control by the operator, as well as the flexibility of remote radio control.

Solution

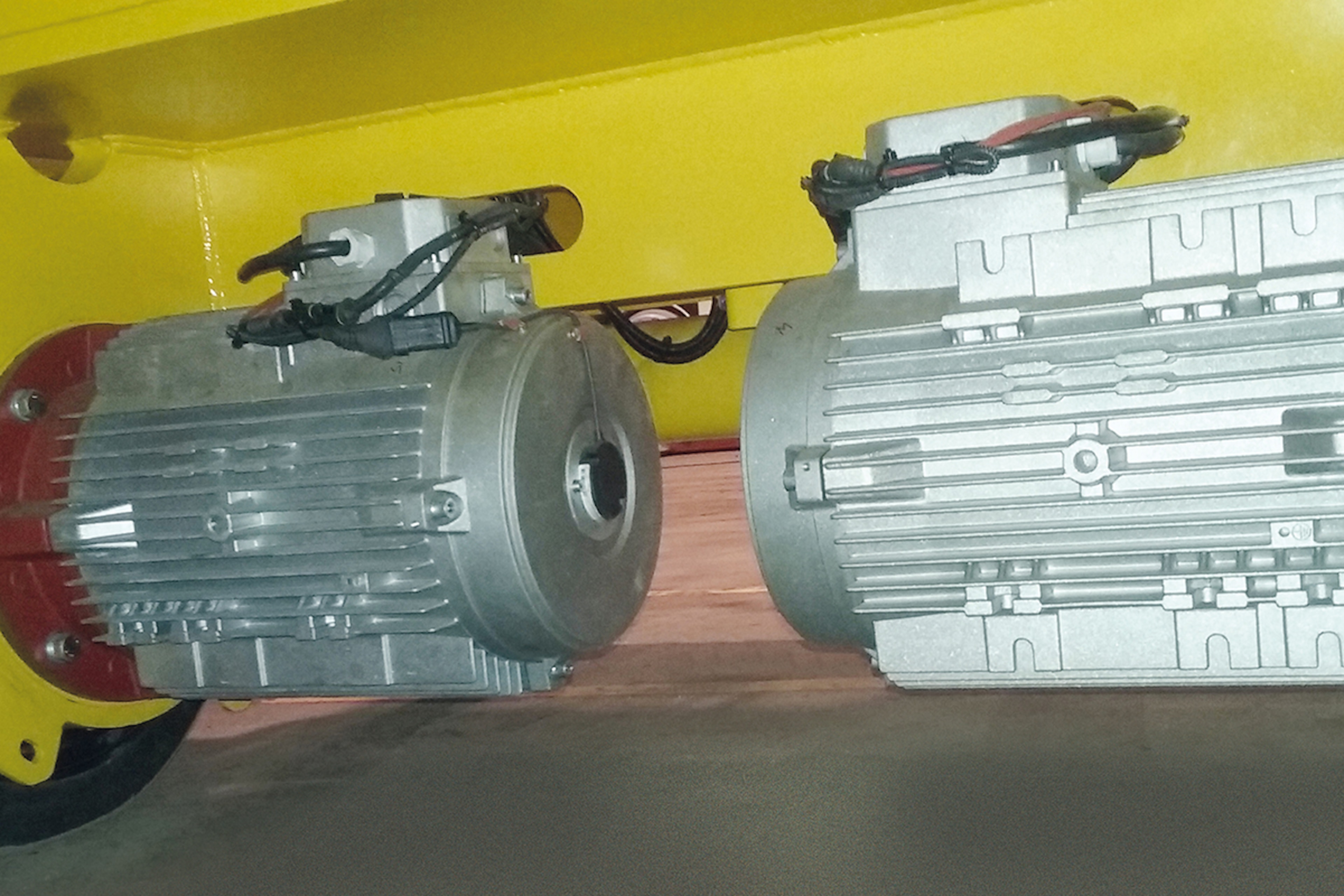

The advanced control of AC induction motors fitted to each wheel-drive gearbox was achieved using individual controllers. Start-up ramps and speeds were programmed to achieve the traction required.

By utilising the software interface for position and speed feedback from each motor, we achieved minimal wheel spin, leading to four times the lifespan of the rail wheels and complete control of the load being hauled.

The hydraulic-controlled brake-release system, coupled with spring-applied pressure release hub braking, provided individual wheel braking and gradual emergency stopping. This was integrated into the air brake e-stop system for wagon brake control.

Benefits

The dual road/rail transmission drive system provides peak efficiency in moving heavy loads of up to 500 tonnes (machine weight 11 tonnes) on rails.

The ability to program variable speed outputs for road and rail drives 20kW AC motors are close coupled to 30:1 reduction gearboxes with spring applied pressure release brakes, providing significantly improved traction control.

This system enables the machine to be moved with greater accuracy when moving wagons into position for wheel maintenance, which is carried out by a lathe that requires + or – 10mm using the inching function or the remote control.

An efficient failsafe braking system with a tight turning radius on road drive with build in linear-position feedback actuator, provides vehicle developers with a highly cost-effective combination of power, performance and functionality.

Get in touch

Do you need support with your next HPU project? Speak to our Major Projects team today.