What is Bundy Tubing?

Flowtech

Looking for specialised tubing for high-pressure applications? Look no further than Bundy Tubing, which is the go-to style of tubing for applications requiring strength and durability.

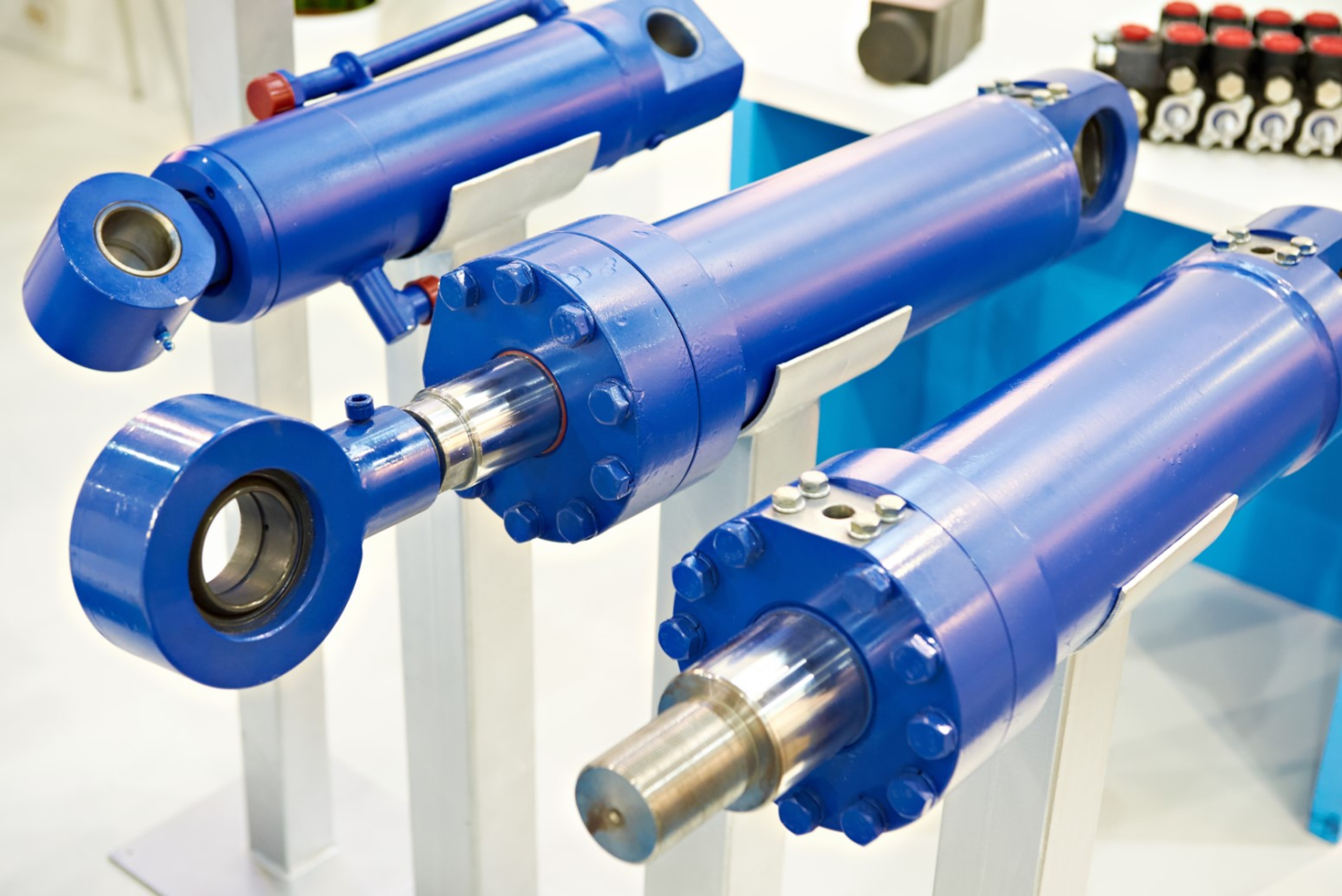

With its double-walled bonded construction, it is a reliable form of tubing that is most commonly used in the automotive industry for hydraulic systems, brake lines and fuel lines.

What is Bundy Tubing?

Bundy tubing, also known as Bundy pipe or Bundyweld, is a double-walled, copper-brazed steel tube formed by rolling a copper-coated steel strip into a continuous tube and brazing it to create a strong bond between the two steel layers.

What are the key benefits of Bundy Tubing?

- Double-Walled Construction - the double-walled structure provides excellent strength and integrity

- Material - low-carbon steel with a copper-plated inner surface

- Corrosion Resistance - often zinc-plated and yellow passivated to protect against corrosion

- Formability - can be easily bent and flared for use with compression fittings

How is Bundy Tubing manufactured?

Bundy Tubing is manufactured through a process known as Bundywelding, which is used to create the double-walled tubing through resistance-brazing. A copper-coated steel strip is rolled into a tube, overlapping the seam, which is then resistance-brazed. This forms a very strong, bonded tubing construction, which makes it very durable, as well as flexible.

Manufacturing process:

- Copper Coating – steel strip coated with copper

- Wrapping – rolled 720 degrees to form double-layer with an overlapping seam

- Brazing – passed through a brazing chamber where the two layers fuse together

- Cooling & Quality Control – tube is cooled and inspected using an eddy current scanning device

What is Bundy Tubing used for?

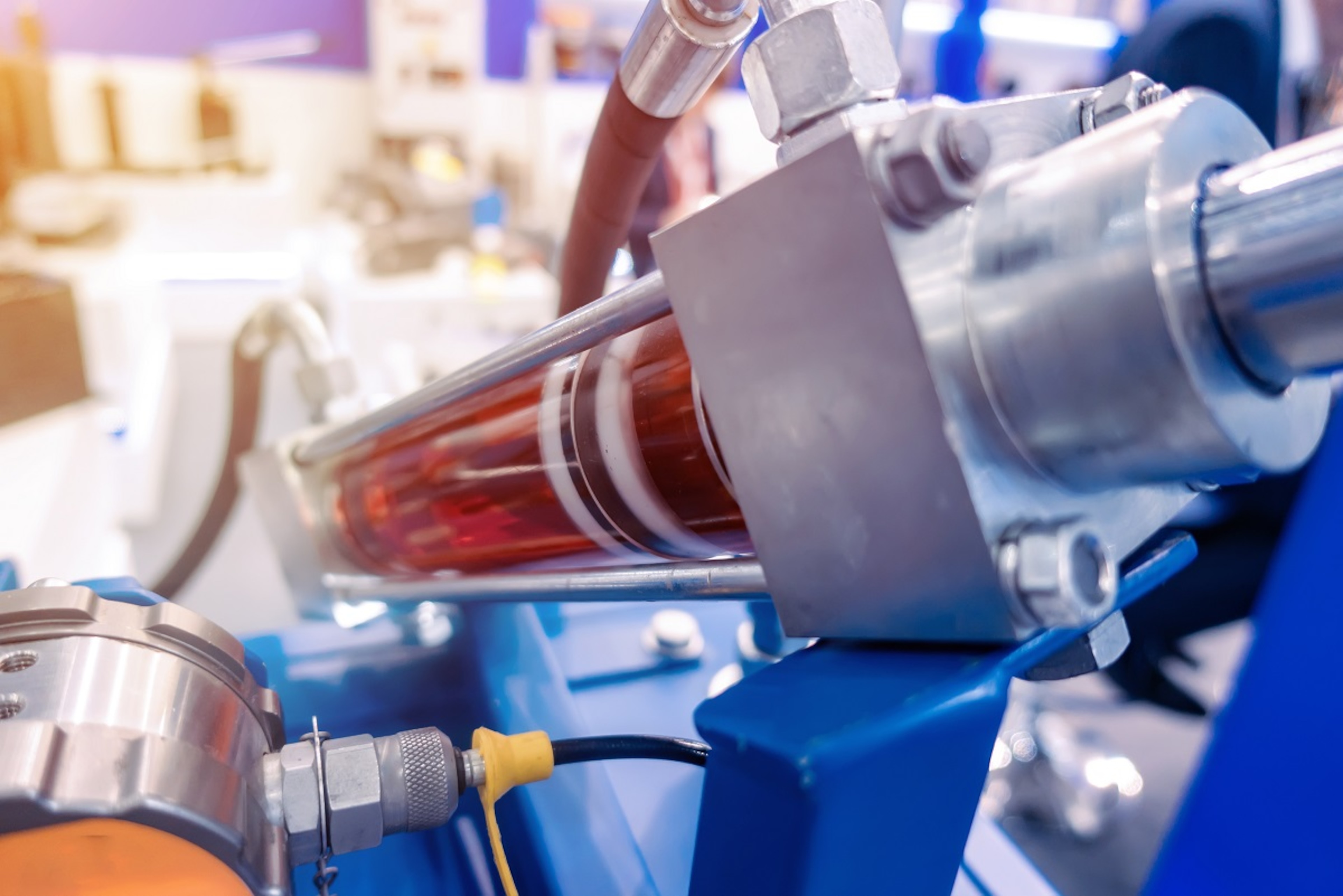

The construction of Bundy Tubing makes it ideal for high-pressure applications, especially in the automotive industry for brake lines, fuel lines, and hydraulic systems, due to its high pressure and vibration fatigue resistance. It is commonly used in industrial settings, as well as high-pressure fuel injection and compressor lines.

What are standard Bundy Tube sizes?

You will find that Bundy Tubing comes in many standard imperial and metric sizes, measured by the outer diameter, including imperial sizes such as 3/16", 1/4", 5/16", 3/8", and 1/2", and metric sizes such as 6mm, 8mm, 10mm.